9/18/23 – 9/22/23

This past week I worked with the new Growbot team. The bot was disassembled during prototyping at the end of last semester. We reassembled the bot and flashed new code onto it. It now has limited movement.

Later in the week I reorganized and reworked the new code so that the new team can understand how it works and can easily make changes.

I helped with lab organization & cleanup.

Coco Fab is currently working on the melting subassembly.

9/25/23 – 9/29/23

I created sketches of coco fab ideas. Researched posable parts for melting control.

10/2/23 – 10/6/23

Created safety manual for for angle grinder and drill press. Updated sketch to available components.

10/16/23 – 10/27/23

Worked with Growbot to fix small code error, and tested ideas to solve what happens when controller disconnects. This found a hardware limitation of RC receiver.

Chocolate Fab- Created BOM for prototype. Ordered initial parts. Created post of initial design.

10/30/23 – 11/3/23

Electrical drawing created for heating control

Heater prototype parts received. Currently creating mounts for assembling prototype. The plan is to avoid irreversible changes to parts until the prototype proves the concept.

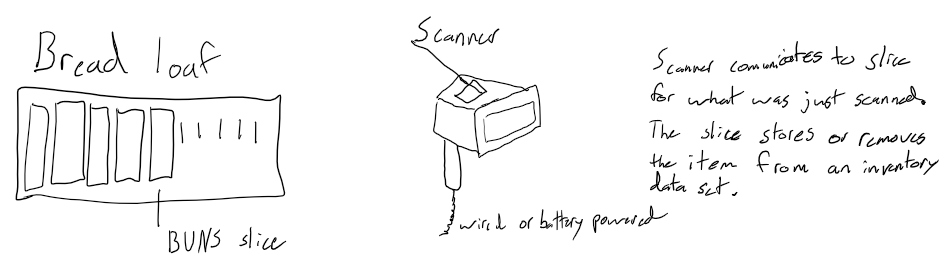

BREAD BUNS:

1/22/24 – 1/26/24

My team and I put together a general plan and list of parts for what we expect to work on over the next few weeks. We drew simple sketches of what we understand our project will be to ensure we all understood each other. Here is my sketch.

We ordered parts this week to get a jump on building a prototype. This next week I will read more of how the BREAD system is setup. I will also be researching existing open source barcode scanners and inventory management systems.

1/29/24 – 2/2/24

This week my team’s parts arrived. We started designing software to run the modules on an Arduino. This next week the new parts will be tested with a first version of the code.

2/5/24 – 2/9/24

This week we assembled the scanner and uploaded code to scan bar and qr codes. We are able to read in the codes and print them to the serial. The next steps are developing the inventory system, design a housing for the scanner, setup the scanner’s screen, and research ways to increase the range of the scanner.

2/12/24 – 2/16/24

This week we worked on the radio communication, scanner case modeling, and handheld options. Currently, we got some transmitters to “send” a packet of data but the receiver has not been able to receive them. A hand held option we are considering is using a USB scanner that connects to and Arduino that transmits the data to the loaf.

2/19/24 – 2/23/24

This week my team worked on our CDR presentation. The presentation was given feedback on ways we could improve our project. One suggestion was that scanners that communicate with UART could be directly connected to the radio modules. Because of both communicating with UART the radio module could be programed to transmit directly what is received from the scanner. Other suggestions were made on simple improvements to our current plans.

3/4/24 – 3/8/24

This week my team tested the wireless communication with the UART radio modules. These modules provided an easy way to send barcode data and many other forms of data with ease. The first prototype of the dataset server was also tested. My next task is to create cad for mounts for the scanner and add a screen.

3/11/24 – 3/15/24

This week I worked more on the wireless communication code. The wireless modules are able to send the read strings consistently and can also have secondary information sent with it. The usb scanner, usb module, and oled screen has been ordered for the next step with the scanners. This next week I’ll setup code for adding the new screen to the existing scanner.

3/18/24 – 3/22/24

This week I made a prototype code that utilizes a 1in screen for the mountable scanner. I will be assembling and testing the scanner with a screen this next week. I will also start writing code for the handheld usb scanner. I will also be helping with the prototype mounts/ frames for the scanner. The 3d models will be printed, tested and revised this week.

3/25/24 – 3/29/24

This week I added the screen the scanner. I tested the prototype code that displays the scanned input on the screen. The code needs improvement for ensuring all the characters are printed on the screen. This next week I will continue working on the code and work on the handheld scanner.

4/1/24 – 4/5/24

This week I got all the scanned characters to print onto the scanner’s screen. The usb scanner is currently not communicating to the usb to serial module. There is nothing sent over the uart communication when the scanner scans a barcode. When the scanner scan a barcode, it beeps 3 times vs the normal 1 beep. The documentation I can find on these error codes says the 3 beeps mean the scanner is not linking. This next week I will be researching how to link the usb scanner and I will be adding a display to the receiver/slice.

4/8/24 – 4/12/24

This week I got the receiver to display to the screen and send the scan information to the raspberry pi. The scanner is no longer limited to the size of the buffer for the max characters in a barcode or QR code. The code communicates an end of transmission that lets multiple uses of the buffer join for the entire transmission. I was unable to solve the USB scanner having a linking error. This next week I will research more into this error. I will also be recommitting my Arduino code and and ensure my documentation is precise as this semester comes to a close.

4/15/24 – 4/19/24

This week I reformatted my code to better explain why each line is used. Additional testing was done this week for the communication from the Arduinos to the raspberry pi. Small adjustments were required for the information to be write the scanned info into the server. I also helped other teams 3d print some parts and debug why a laser was no longer operating. This next week I will be setting up a demonstration of the working hardware.