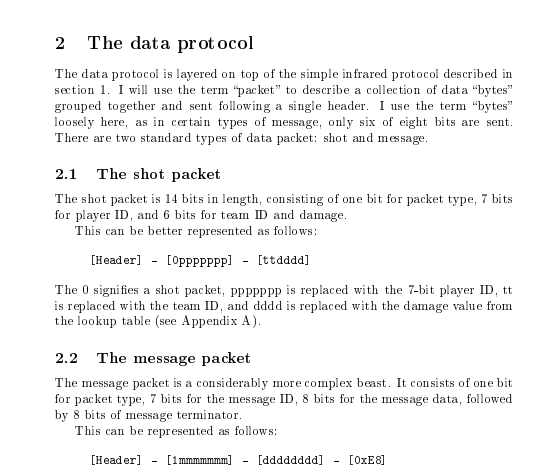

reading and understanding the signal types for laser tag protocol

these protocols are used in the guns to change the settings and is a guide on how they communicate

Worklog update 2

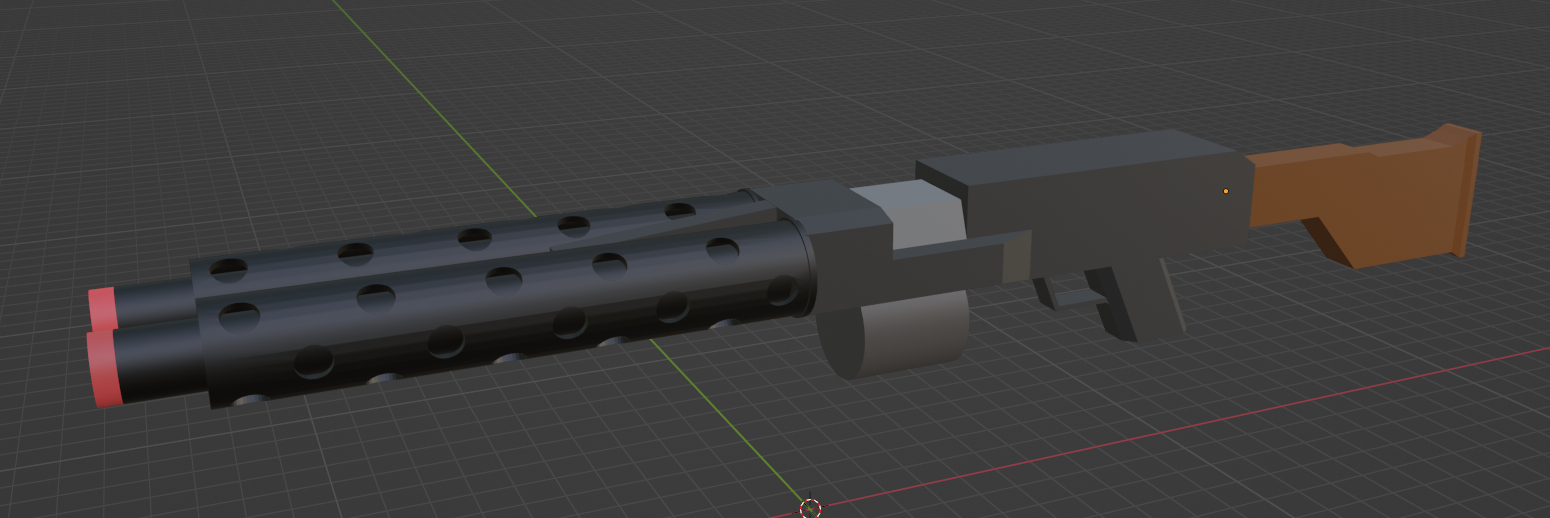

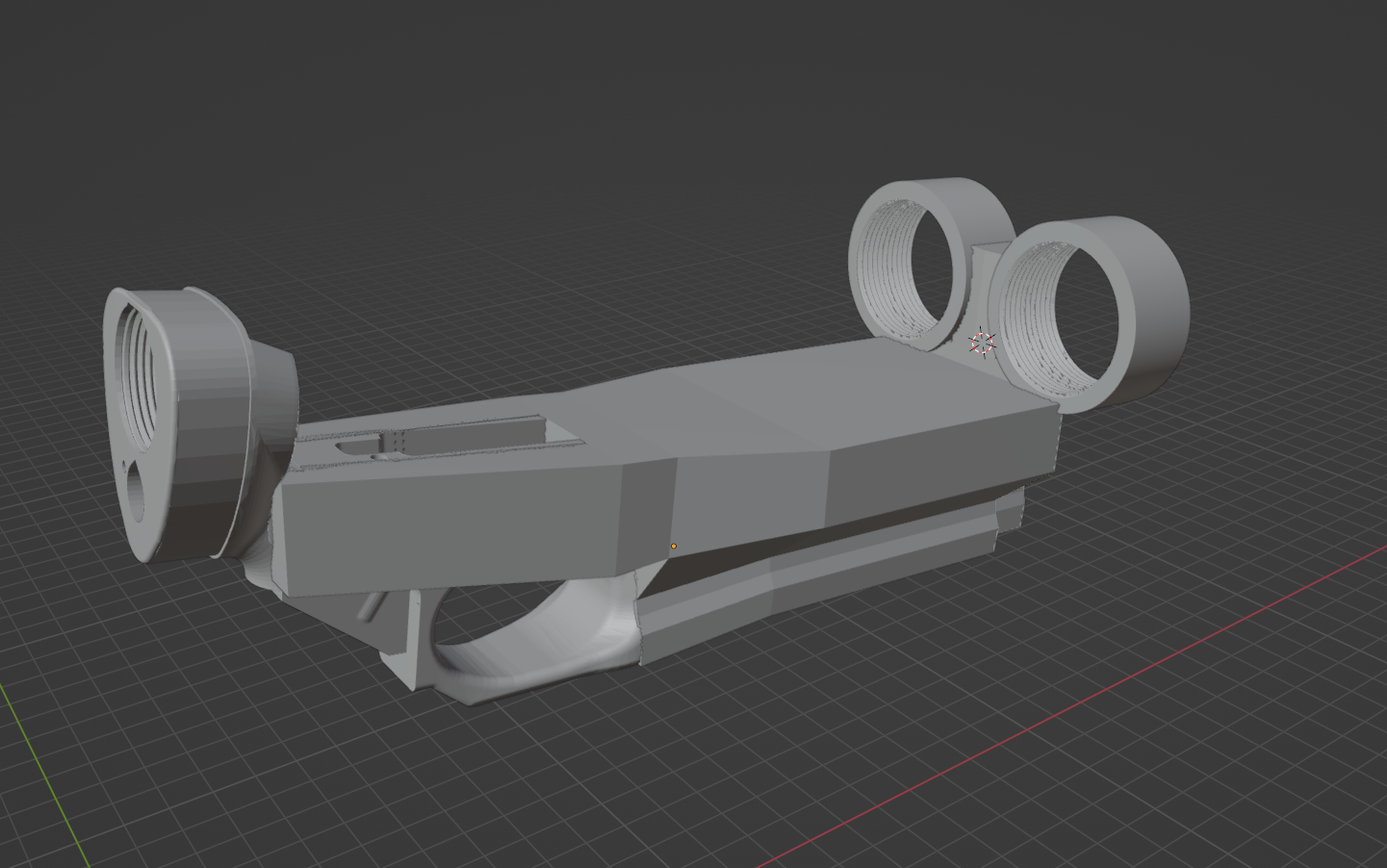

over all i have been working on 3d modeling a casing for our lazor gun we are shooting for a double barrel machine gun and so far am working on figuring out what materials we can use that exist for example using pvc pipes for the barrels and some existing gun parts for other parts of the gun like a grip the tricky part is to take the 3d model and convert it in to something that can actually be printed and parts and things can be put in

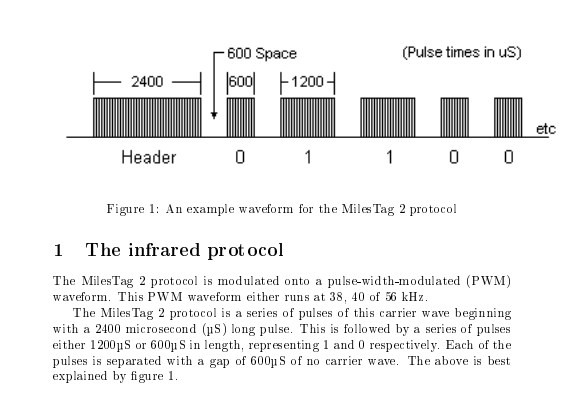

here is a old early picture of the model i am working on i am also trying to figure out the style and direction i want to go with it there are a lot of possabilitys

Worklog update 3

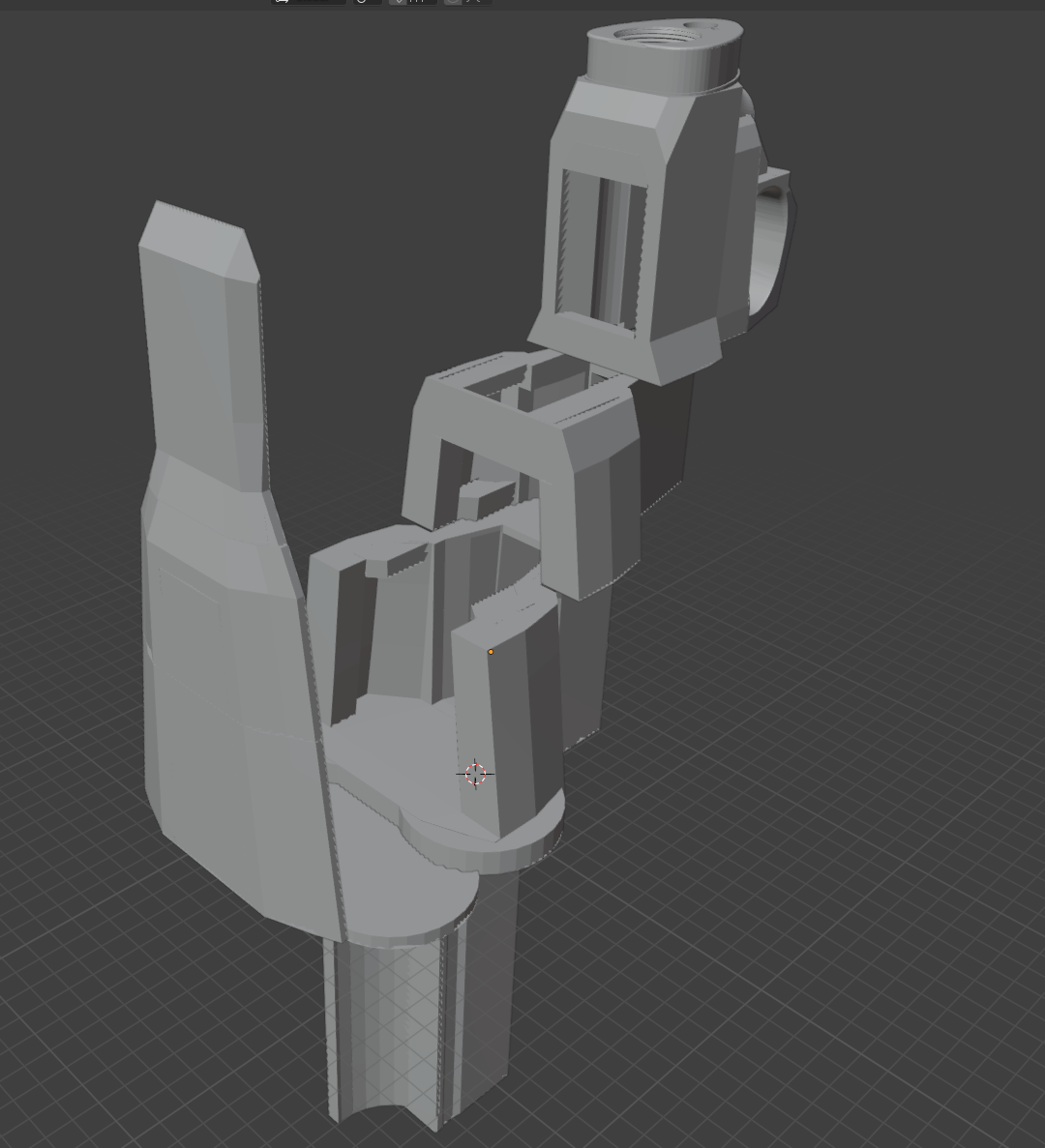

this section of the project has all been 3d modeling i made this 3d model what we want the gun to look like and since then i have been learning how to remake this in a cad software so it can be 3d printed i have done work with blender witch if more of an artistic software i should start to be able to start printing parts soon

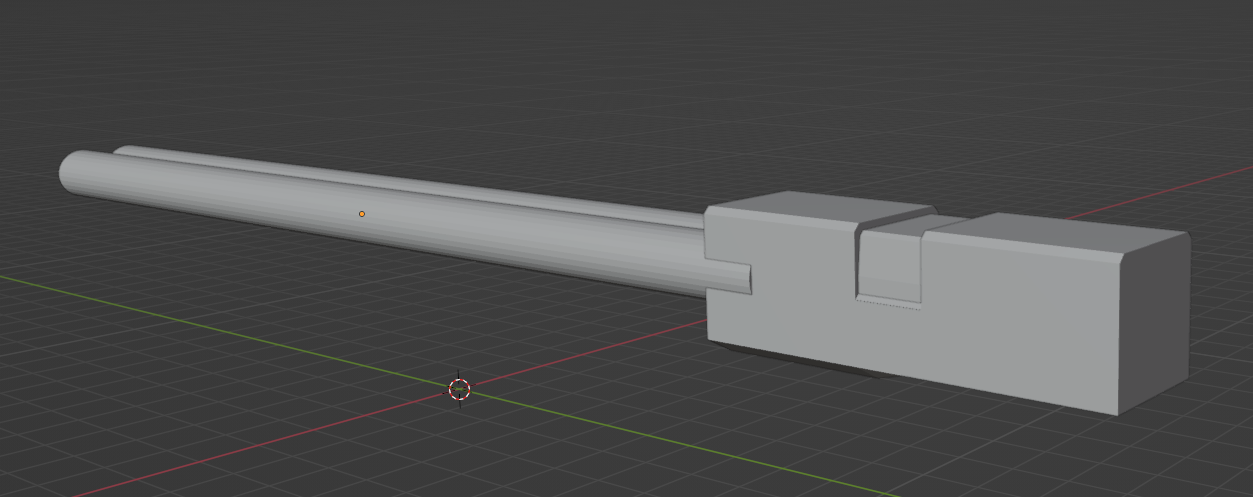

Worklog update 4

I have made a testing platform model to start mounting the hardware to with out all of the decreations it still needs some work and i need to figure out how to best split it up for printing and maybe hallows out some spots it not quite done that dont need to be as strong but it should allow us to make the entire lazor gun it has threads for a buttstock and a place for a trigger and grip and threads for two pipes for our barrels but i should be able to start printing it next week

WORK UPDATE 5

A new semester and more progress to be made at the end of last semester we had a full shell done and glued together it look like what we wanted but had some flaws as in it had not great access in to the compartment of the gun and the parts had no good spots to hold themselves together other than flat surfaces so i have re done some of the design and added some screwable surfaces and a better access panel i also extended the front to help with the barrels going towards each other and to give more grip

next week i hope to refined this a little more and talk with my group members for a revision and input then hopefully start printing the parts should be smooth sailing if the printers behave

WORK UPDATE 6

the model got fleshed out a little more and I cleaned up all of the Ngons that would reek havoc in printing so it should be ready to print but i need to figure out a some kind of hatch system for the top plate if i do a hinge it need to lock in some how so it doesnt flap open during play im thinking magnets but then there is the issue if mounting it in the plastic and strength of them i want it to be easily opened but secure also the barrels need to be figured out for the metal and how the lenses are going to fit

WORK UPDATE 7

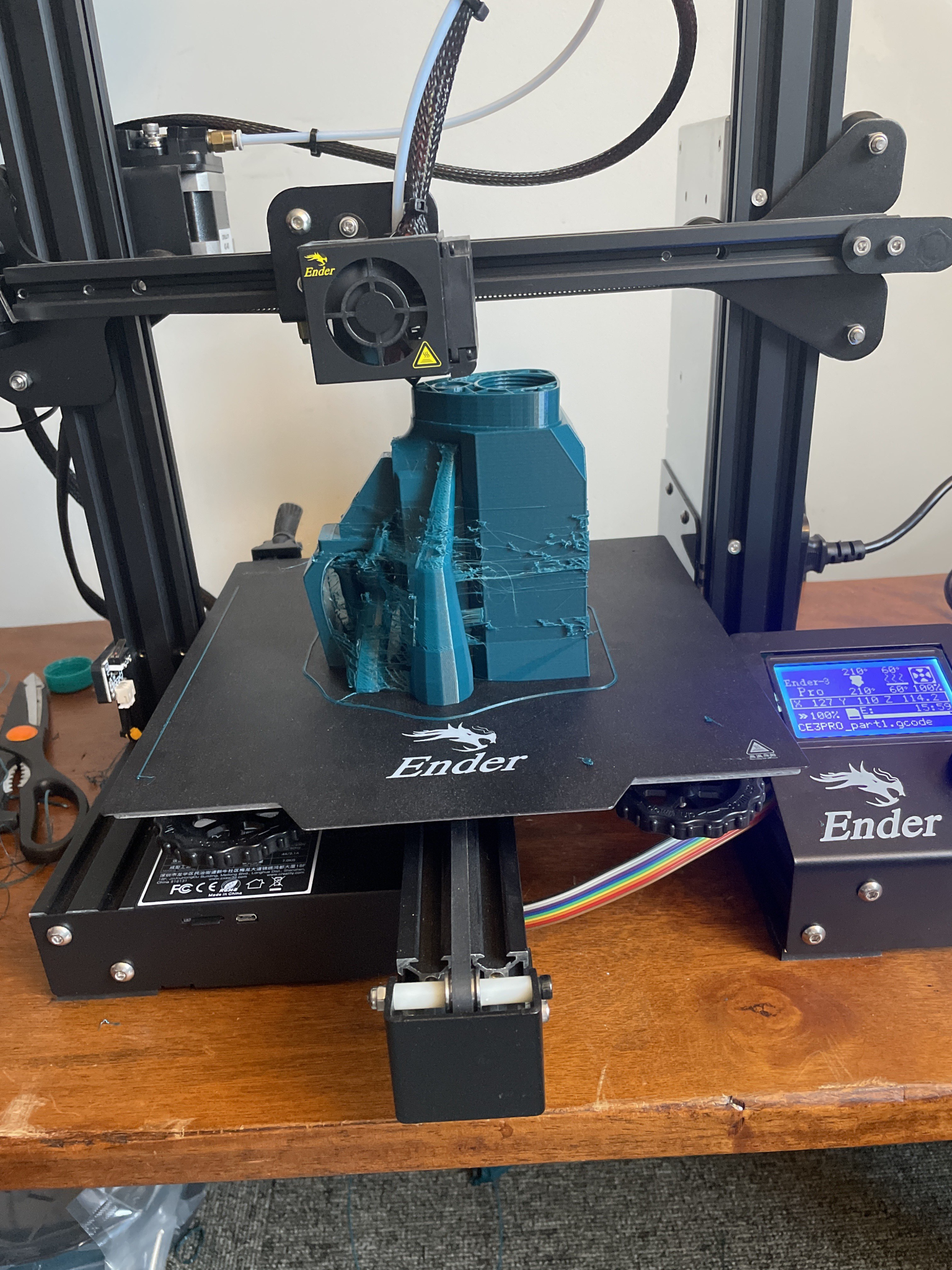

This week i got the model ready for printing and have started to get some of the prints done i’m hopping i can get it done before the mid semester meeting so we can show the mk 2 its just going to take a long time to get everything printed. i’m hopping to get a printer from a friend so i can print 24/7 at home

WORK UPDATE 8

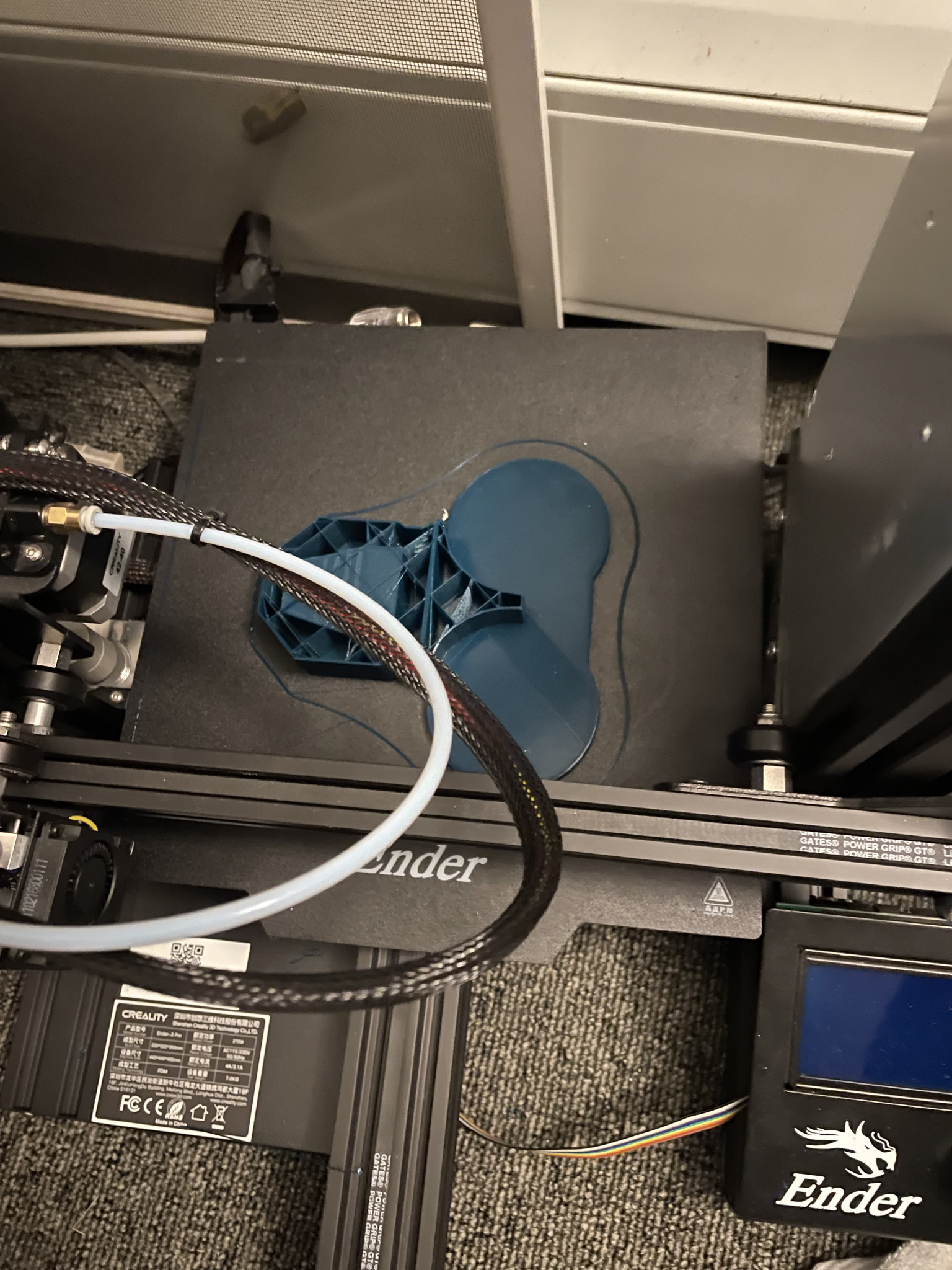

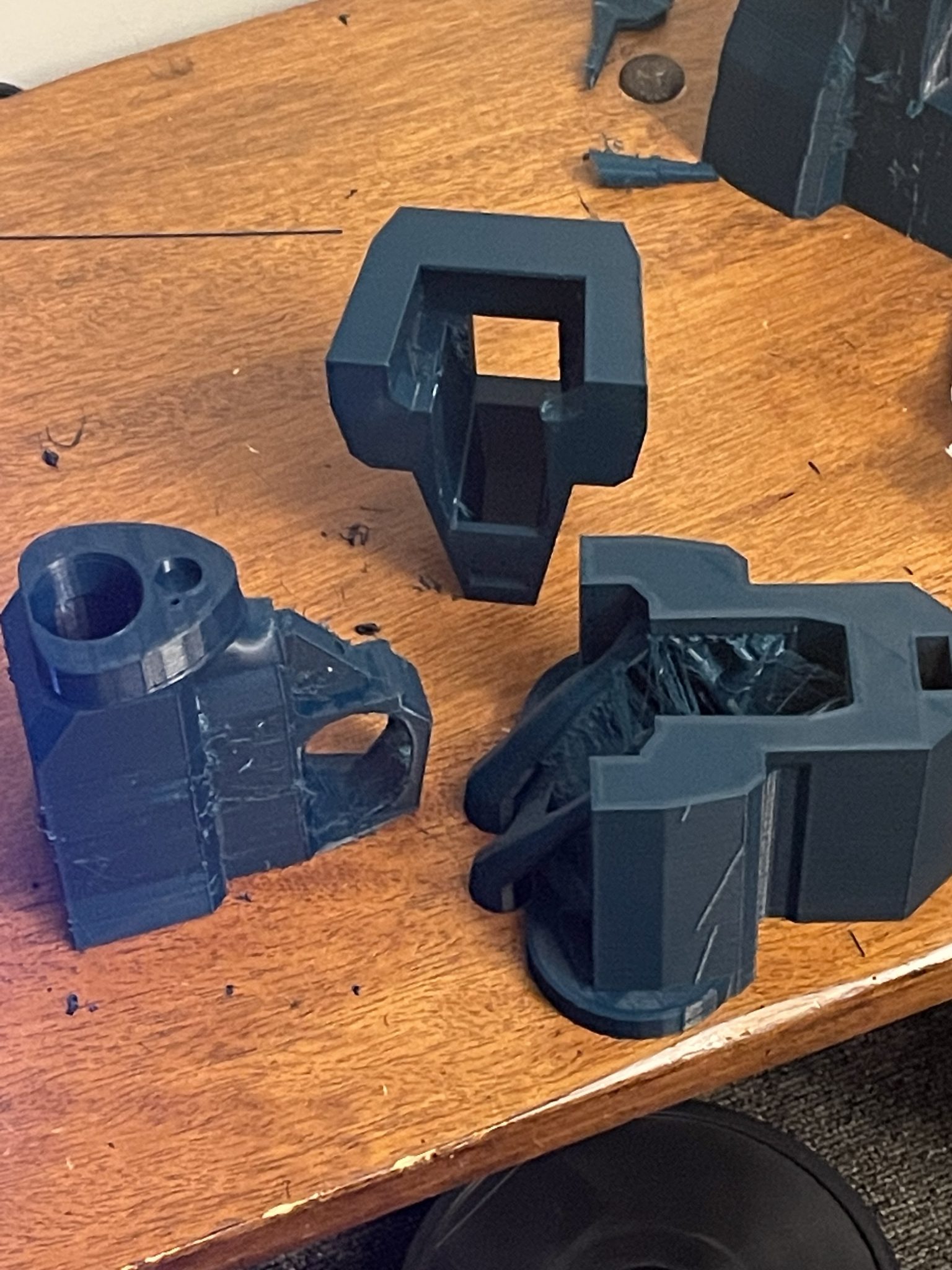

I got the printer set up and printing it caused no end of issues but i got all of the parts printed for the mk2 casing next is just to screw them together and it will be ready for our mid summer review and moving forward puting the electronics inside of the parts

WORK UPDATE 9

in the wake of the review some things came up one thing is the next thing for me to do is the mk3 ceasing i need to mark out and put the right holes in so it can all be bolted together and we need to get working on the barrels so they will have a good strong fit i have been ajusting the design this week to fit the things that came up then i should be able to start printing the gen3 next week

WORK UPDATE 10

Mk3 model is done and now the next step is to just start printing all of the new parts this has had a few issues but most of them where already ironed out in the mk2 so now its just going to be a lot of printing

WORK UPDATE 11

The 3D printing is going well there is about 75% done I had to go back and make some changes to the model and I think i figured out a good way to make the top so it can open Im going to make it hinged with a locking key on the side this also goes along with all of the other guns at the place

something like this this way it can stay securely down I also think throwing some magnets in might be a good idea and in terms of adding to the gun all that would need to be added is a small slot

WORK UPDATE 12

3d printing is still going as well as can be expected the next big step i think is to make a plan for the stock on account of the stock being a standard brand ar15 stock there are guides out there on how they can be made so i have been poking around to see what one might be best and found

https://www.youtube.com/watch?v=4L7_PKM_M9E&t=175s

this is a fairly detailed video he does use a nice walnut and i would most likely make it out of pine as its the easiest to find around here but i plan to make 2 so if one doesn’t turn out the way i want i have a back up

WORK UPDATE 13

the 3d printing is still going i had to stop for a bit to get more filament for my printer but other than that a few parts have failed but i need to look in to the barrels we always wanted metal barrels for protection of the sensitive parts but it leads to an issue of metal and plastic dont like to bond so as a result i need to find a way to put a plug with out lense and led inside of a metal barrel and have that attach to the gun on the mk2 body we have the rings that the shroud sits on these might be good to extend then use some apoxy to get the barrel in the gun then i was thinking of a plug that would side down the barrel and then afix to the back so it could be easily removed one issue with this is getting the lense in the right position but that will take tuning nonmatter what

WORK UPDATE 14

This week I ordered the aformechend key lock and last weeks printing pause allowed me to look at the parts and make edits the forend now has better bolt placement and the place where the lock will go to hold the top plate down was made it will require a custom locking wedge but should be no issue i also have gone back one of the other things i want to do for the top is to install magnets so during play it will stay shut going forward i need to go buy some metal pipe the group is torn between taking an existing gun and using its assembly or making our own we will see what the sponsor is willing to do

WORK UPDATE 15

This week i got the 3d printing finished and the barrels where purchased now all i need to do is to put it together with some bolts and i also need to make the wooden stock but that’s not my highest priority over all i’m hopping to get everything put together for design expo and then if i cant get every little bit finished i should be fine to finish before the final turn in week

WORK UPDATE 16

this week i was in the lab for a long time i got the trigger installed with its switch and the whole peace glued togeather then the barrels put on the gun requres a few more little details i would like to get a wood stock made but we will see and i would like to get some outher small tuches done but its 90% there and ready for the electronics to be installed

(insert pic)