Work Log September 29th, 2024 — Filament Flip Flop

During the period of time over the past week I was able to get the raspberry pi set up but not the Octoprint instance due to a few hiccups. The raspberry pi created a few issues when trying to get it set up that lead to a large amount of time being spent on troubleshooting why the raspberry pi would not work. The initial issue was a bad image of the raspberry pi os that lead to me being unable to sign into the pi do to some misconfigurations in the files. After solving this and getting access to the pi I had some issues setting up ssh. I was able to ping the device with 0% loss but when trying to connect via ssh the connection would time out. While digging into config files I found that I needed a character(‘#’) that was not available on my current keyboard config so I attempted to change the keyboard config. In doing so I actually made a character that was part of my password unavailable so I was unable to log into the raspberry pi. From this I had to re-image the system. After reimaging I encountered the same issue and was unable to get the pi to connect. After digging through the config files for ssh I was able to find some settings to enable root log in over ssh and allow password authentication. Once these settings had been applied the pi then gave me a message “declined connection” when attempting to ssh. Finally, with the ssh properly set up and connection being online through clearpass I was able to find out that the mac address in clearpass was incorrect. With this it is still unclear how I was able to ping the pi but not connect via ssh through the network but after correcting I was able to get the pi connected to the network and enable ssh.

In the coming week I plan to:

- Install an instance of octoprint on the raspberry pi.

- Get the Raspberry Pi connected to an Ender 3 S1

- Start and run a print through octoprint.

Work Log September 22nd, 2024 — Filament Flip Flop

Over the past week, I began working to set up an instance of Octoprint on my Raspberry Pi but ran into a couple of issues. The first was that the device’s mac address was not listed on the packaging so I could not register it with MTU’s clear pass network so it could not connect to the network. Since it was unable to connect to the network I could not discover it on the network to find the IP address so that I could connect through Octoprint. One solution to this is to use a screen but I did not have any that would work on hand as the Pi only has a micro HDMI as output. I placed orders for a small monitor and a micro HDMI to HDMI cable so that I can get the screen to interact with the Raspberry Pi.

In the coming week I plan to:

- Finish the install of the Octoprint to the Raspberry Pi

- Get the Raspberry Pi connected to an Ender 3 S1

- Work to understand how Octoprint Interfaces with the printer

- Start to work through the program files to understand where things are located

Work Log September 8th, 2024 — Filament Flip Flop

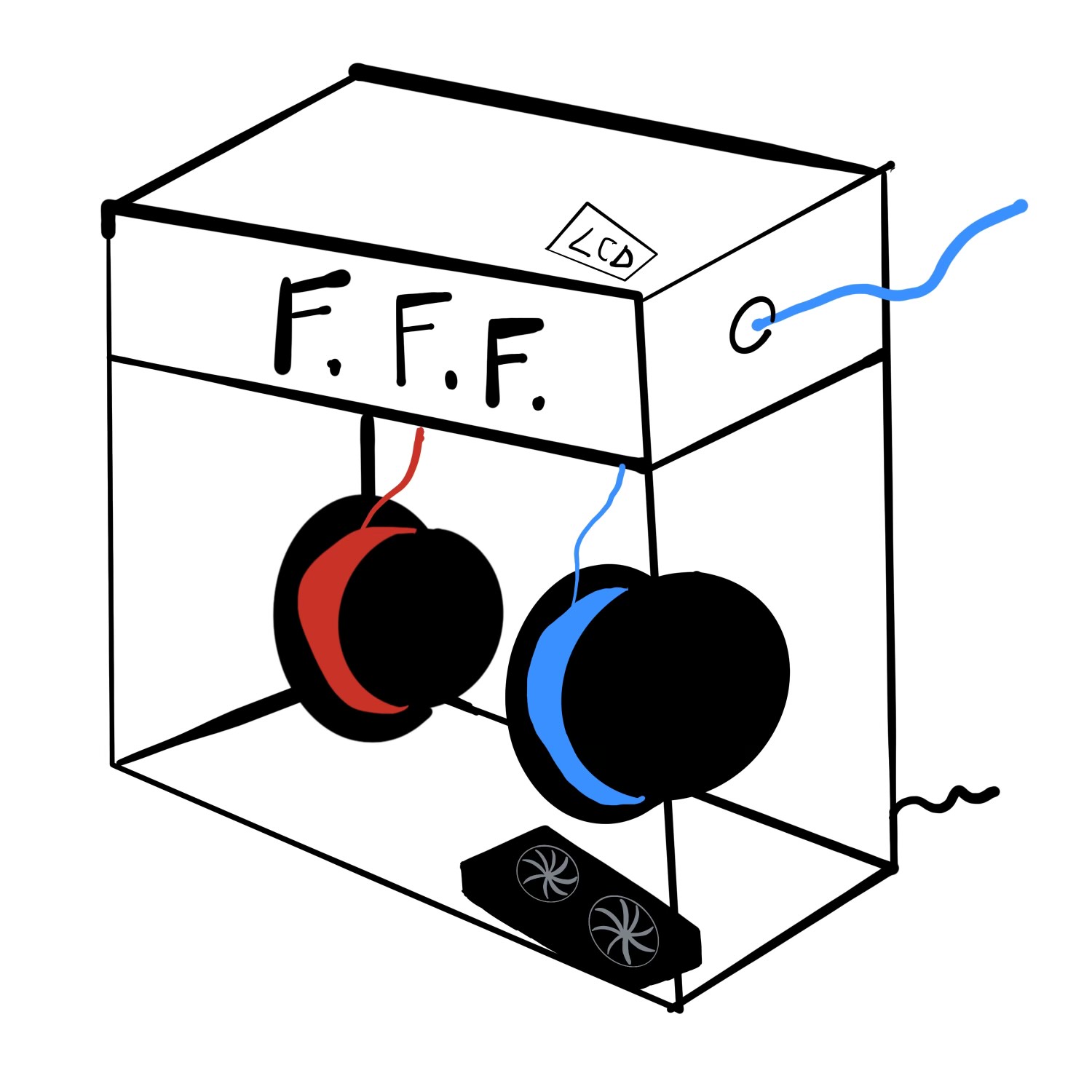

Over the first few weeks we have been working on narrowing down the project itself and trying to draw an image of what the final product should be. We have decided on Filament Flip Flop(FFF) being a multi material system that includes a filament dryer system. This system will connect to a 3d printer to both improve its usability as well as provide the ability to operate with multiple filaments and reduce the water content of the filament they are printing with. I specifically have been assigned to work on a few specific tasks. One of these is setting up the 3d printer controller software and getting it running with a printer. Another is how this controller will interface with the multi material system. The other system that I have been put in charge of is the temperature and humidity control and sensing. The first of these that I plan to start with is the controller software.

In the coming week I plan to:

- Install OctoPrint on a raspberry pi

- Connect the raspberry pi to my Ender 3 s1

- Test to begin understanding how OctoPrint communicates with the printer(printer uses the marlin firmware)

- Start digging through the program files to see where edits can be made to add functionality.

Work Log September 2nd, 2024 — Getting Started

With the kickoff of the new semester I have been getting familiar with my new project, Filament Flip Flop, and getting the project specifications and other documents and getting started. Stay tuned for more updates!

Work Log April 20th, 2024 — ReStruder

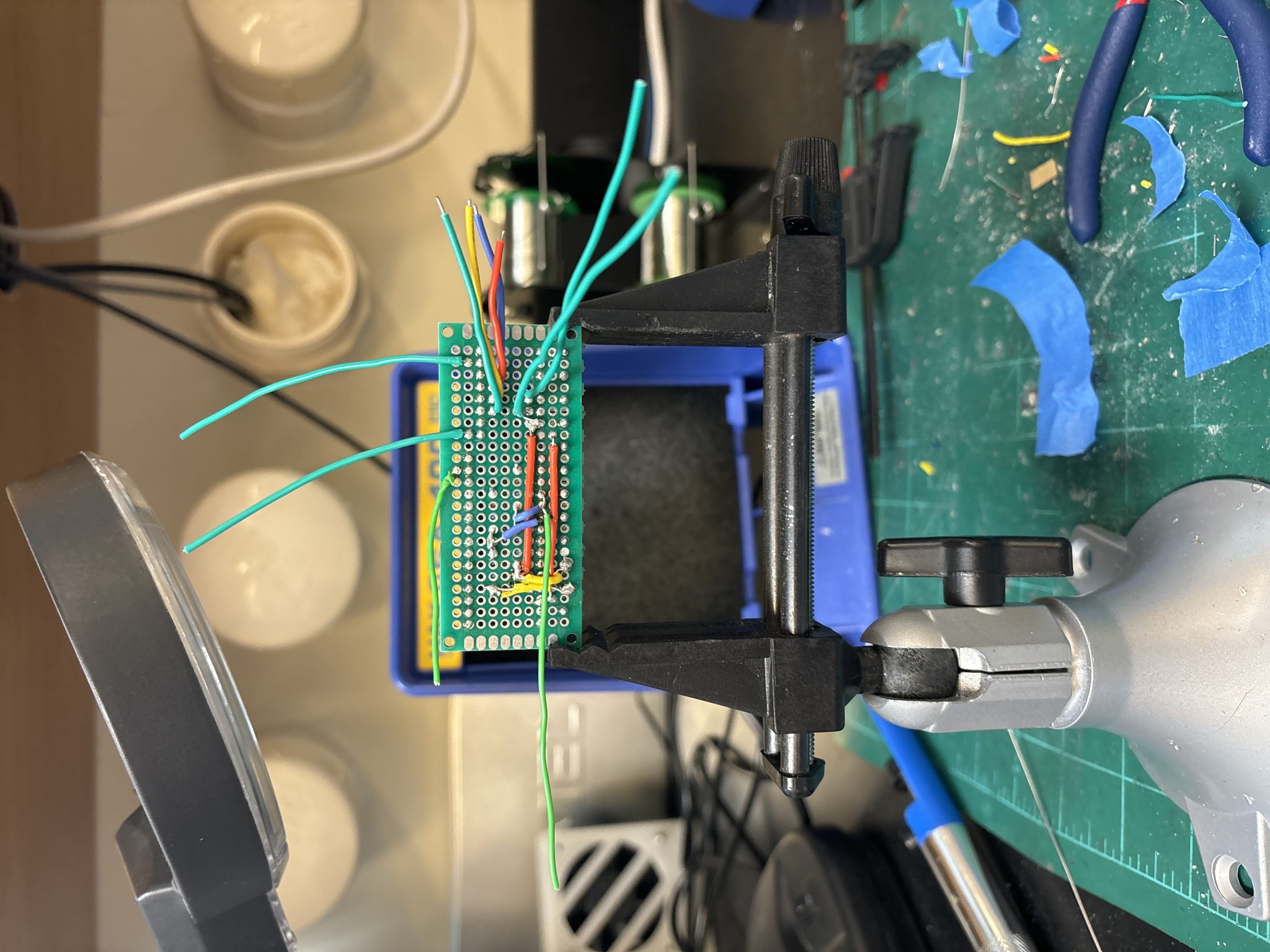

Over the past week I have worked on recreating and developing a second iteration of the prototype boar to use for the project. This board uses the same drawing from the previous board while shrinking it to fit a smaller footprint that will help to minimize the size of the device. This was also necessary as the prior board had some mechanical issues that would limit the movements of the extruder as it would crash into different parts of the 3d printer causing it to not work as intended. Additionally, there were some wiring errors that did not allow for the board to function as intended. The recreation is intended to specifically address these errors though there are some other factors that need to be figured out outside of this board that have hindered the testing of the board to be put off until next week. I created a spreadsheet that details my plan for implementing the board Spreadsheet showing the layout of the board.

In the last week of work on this project I plan to:

- Test the board and see if the board functions as expected,

- Work on and turn in the end of semester project report,

- Meet with Shane and my team members to present the project and receive a final grade.

Work Log April 13th, 2024 — ReStruder

Over the past week The physical project fell behind so I shifted from code focus to that. I personally spliced the wire bundle for the wires that we need to run our system and then back so that we can implement our circuit board. One of the issues was that there was not enough wire to be run do I has to connect some extra wire to the old to help lengthen them. I made sure to get the same gauge and color wires so that it was consistent. This should allow for the project to be connected within the next week.

In the next week I plan to:

- Get the system hooked up to the printer and start testing its operation,

- Get thje code uploaded to the board so that it should be able to function as intended,

- Do our first test print with ReStruder!

Work Log April 7th, 2024 — ReStruder

Over the past week I spent most of my time working on the project draft, social media post, and other parts of the project that did not result in physical manifestations. One of the main things that I did was work on uploading all of the code and important information to the project from my personal to the project drive. Another thing that took more of my time this week was submitting a proposal for a project that I want to start next semester.

With this, Over the next week I hope to:

- Get the code uploaded to the project as the physical portion has been made.

- Run some tests to see what the current system does.

- Start developing ways to test the current setup and get data from it.

Work Log March 30th, 2024 — ReStruder

Over the past week I had a lot of outside factors come up and was unable to spend time working towards completing either of the two goals from the previous week. This will require the tasks to be pushed to the following week.

My personal Interest this coming week will be as follows:

- The main priority is determining the way in which the harness will be split so that we can obtain the signals that we need and so that we can receive the power from the 3d printer supply.

- If all the parts can be completed and attached to the 3d printer I hope to begin running tests to see the functionality and start developing a program that will also feed out data about the system so that we can work on testing and troubleshooting.

Work Log March 23rd, 2024 — ReStruder

Since the Last Work log I have completed a few main objectives that have helped progress our team to a working final prototype. The first task that I completed was to tear apart some old board that were unsuccessful prototypes to salvage parts to use for our final prototype. The main parts we were looking to salvage were bus bars so that the Arduino could be added and removed as needed and was not soldered directly to the prototype. After this I continued to look into ways in which to process data from the usb port being delivered from the Arduino. I found that I was capable of creating a script that could be run in the command prompt that would create a csv file from the data being given to it. Overall the state of the project is to the stage of implementation. Currently the main tasks are to determine hoe to mount the circuit board, splice into the wire harness for power and signals, and to mount these systems to the printer. From there we will be able to test the program that we have for continuously monitoring the system. Additionally, through the lab cleanup event the drawer was organized.

My personal Interest this coming week will be as follows:

- The main priority is determining the way in which the harness will be split so that we can obtain the signals that we need and so that we can receive the power from the 3d printer supply.

- If all the parts can be completed and attached to the 3d printer I hope to begin running tests to see the functionality and start developing a program that will also feed out data about the system so that we can work on testing and troubleshooting.

Work Log March 10th, 2024 — ReStruder

Over the past week I have developed a testing rig where I was able to get the Arduino to interface with a few different sensors and give a live output of the readings and get the measurements to accurately read. The one part that I was unable to complete is getting the data to then be written out to a spreadsheet so I had to manually analyze the data. With this I was able to see the general trends but I think it would be valuable to be able to get the output to be written to a spreadsheet for better analytics.

For the following week I hope to complete:

- Figure out how to get the data being delivered to the computer through USB to be plotted in a spreadsheet so that it can be used to interpret function of the system to make sure things are working as expected.

- Get started on Implementing the system we have with spreadsheet testing and not just simple circuits I have built.

- Create a program for the main project system that can be used for testing.

Work Log February 25th, 2024 — ReStruder

Over the past week there was not much progress made as I had spent most of my time with exams and projects due before the break for other classes. Additionally, there was a lot of work to be done preparing for critical design review as the problem I was originally going to talk about had been solved. I had been having a lot of issues with understanding the current state of the code but had heard back from the prior team member who developed it in which he gave a very detailed breakdown of the code and a high level idea which has allowed me to understand its function. With CDR then I presented attempting to get a higher resolution from the sensor to better measure the diameter of the filament going into the extruder head as the current assembly. From the CDR I received some great feedback on some ideas of what exactly to do to try and improve this. I gathered this feedback in a google doc and am going to be working my way through implementing it. The first step is to develop a way to test the sensor and quantify its output.

Another thing that happened over the past week is that I received an order of Arduino boards and supplementary parts to develop a test circuits on my own at home outside of the lab to help me be able to make more consistent progress with the project as getting to the lab can be a challenge at times.

My to do list for the next week is as follows:

- Come up with an Arduino circuit and program that can be used to create a graphed output using the interpretation methods used in the main program.

- Add program related resources to the drive in their own folder so that they are accessible to the rest of the team an future team members.

Work Log February 17th, 2024 — ReStruder

Over the past week I spend some time looking over and making some edits to the new version of the initial project specifications, prepared for the upcoming CDR, and ordered a set of Arduino boards and supplementary devices. For the CDR I created a google form for the team to use for obtaining and keeping track of feedback given to us during our presentation slot. Additionally, spent some time working with the team on what to include in the slides and from there have been working on them off and on. I ordered myself a few different kits on amazon along with just some bulk and general sets of items to help me be able to learn more about hot the Arduino boards function to be able to better integrate our system. I have specifically gotten a module that has a hall effect sensor on it as that will allow for me to get used to using the hall effect sensor. On the code side of things specifically I was able to locate a code file that contained many more comments and updates to the functionality of each part of the program so this has helped me understand the purpose of the different portions of the main code body. Over the week I have not done much in terms of updating the drawer and drive organizations so those will continue to be on the to do list for the next week.

For the upcoming week here are the tasks that I hope to be able to complete.

- I plan to work on coming up with design solutions for how we will be able to connect the circuit to the head assembly.

- I hope to attach the current assembly to the printer and verify that it works. It is currently just a recreation of the stock assembly with the diameter sensor attached but no other connections made. this is just to make sure that the base parts of the assembly work to save some trouble shooting time later on.

- Update the resources in the google drive and organize the drive.

- Organize the ReStruder drawer in the enterprise lab to better contain the project and pieces.

Work Log February 11th, 2024 — Restruder

This past week was filled with challenges that made it very difficult to devote time towards the project as there were a lot of projects and exams that filled up the few hours that I do not spend at work. That being said, I had started working more in depth with the code trying to figure it our finding that it was very incomplete and not a very good start even. Because of this I started doing some digging through some other methods of accessing documentation. While I was unable to find the best information in the google drive I was able to by looking through work logs of prior semester team members. Through this I was able to find some other code files along with some models and diagrams that provided me with a much better understanding of the project than I had previously. This did take away from my main goal of working through the education programs that Arduino has so I will need to work on that moving forward to help understand the actual implementation of Arduino and its code.

For the upcoming week there are a few more task that I will be tending to.

- Work through the Arduino education programs so that I can understand the basics around using the Arduino nano. This will primarily be in the form of understanding how inputs and outputs can be made as I have no background in that but other programming skills I have from CS courses.

- I also plan to go through the program and create a pseudo code version of the program along with jot down specific questions and issues that I have when understanding it.

- I would like to work on bringing some of the crucial documentation and resources lost back to the google drive.

- Continue to Improve the functionality of our groups drawer and make it more organized so that the system and parts can be easily identified and worked with.

Work Log February 3rd, 2024 — Restruder

Over the past week I was able to locate the newest version of the code from last semester for the Arduino. In addition to this I got the IDE set up and running on my personal laptop so that I can work on it wherever I am. I was able top get a basic understanding of the IDE but was not able to make full sense of the code as there are a few functions in use that IU have not seen before. I was still able to get the Arduino to connect to the IDE and my laptop to be able to upload the programs top it so that we could, once we get a firm understanding of the way the electronic system will work. I was able to talk to one of the professors on campus here that i know and he is open to helping figure out how to interface the sensor with the Arduino board. Currently I am skeptical of the ability to directly plug the sensor output into the Arduino and believe that there needs to be an amplifier. Additionally, with my work schedule I was not able to spend much time in the lab itself so I was unable to spend time working on organizing the drawer and components that we have.

For the upcoming week there are a few more task that I will be tending to.

- I plan on going through some of the Arduino education programs that they have on their website so that i can get an understanding of how the Arduino works and what might be possible to do. This will help me better understand the current state of the code along with finish it so that it works as intended for the final product of our project. It will also allow me to make improvements to what has already been done if there is space to do so.

- lastly, potentially not going to be got to this week, I want to organize the collection of parts and pieces that are within the projects drawer so that we can better utilize the space and be more organized.

Work Log January 25th, 2024 — Restruder

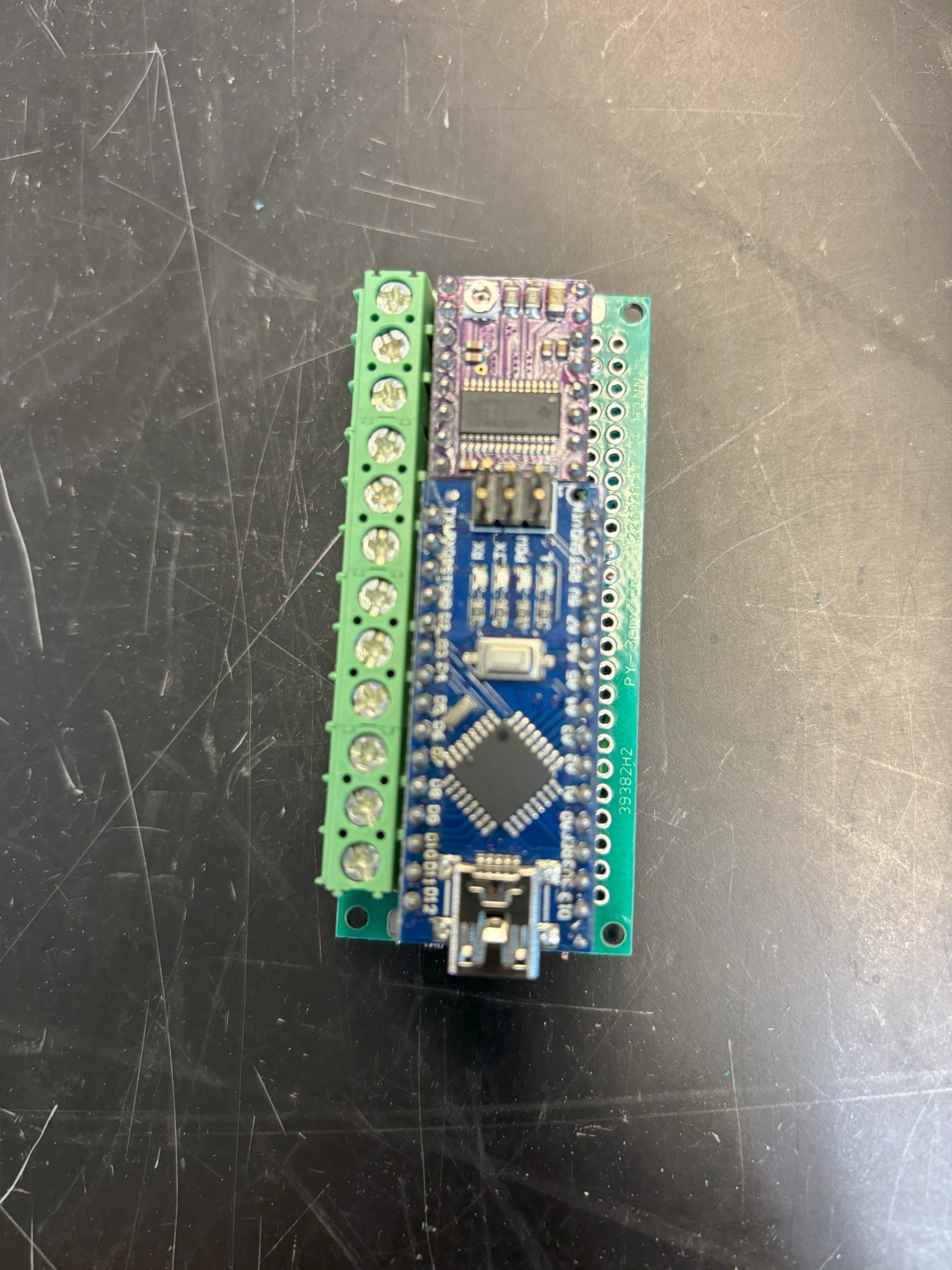

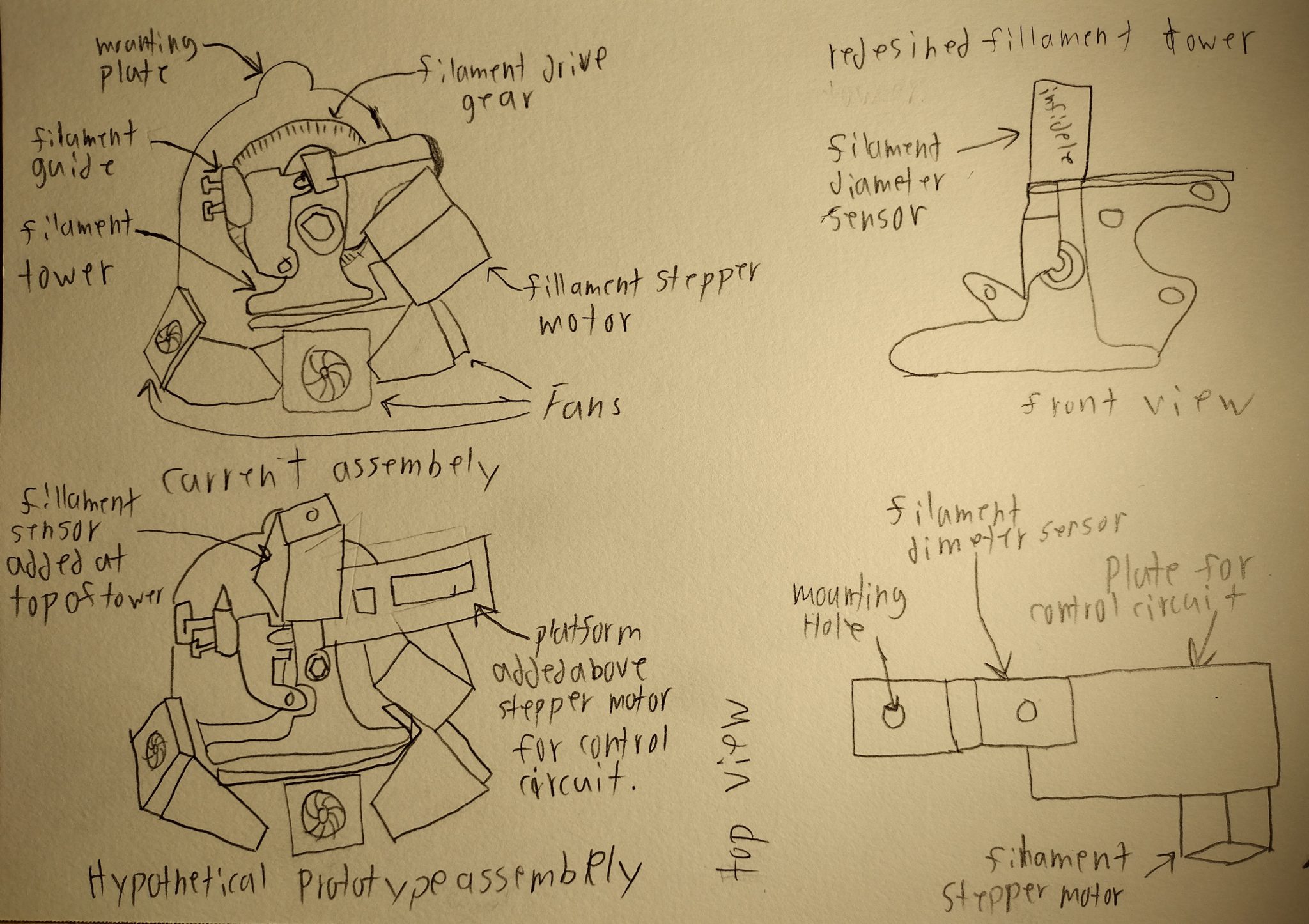

Since the start of the semester I have been working on understanding the goals and purpose of the project I am working on(Restruder). I have been accomplishing this by getting to know my two team members, Lindsey Manhart and Alex Nigrine, who were previously on the team along with reading some reports and documentation within the google shared drive. Through this process I have come to understand that the purpose of the project is to create a system that can be used to measure and dynamically control the rate at which filament is extruded on the LulzBot taz 3D printers. This system will allow for the use of recycled filament that has a larger variation in diameter than commercial filament. The system does this using a magnetic hall effect sensor to obtain the diameter of the filament. This is then sent to an Arduino nano to be stored for use to change the rate up or down to account for changes in the size of the filament so that the extruder has constant supply and pressure. The current state of the project has a full concept for the circuit and program and is in the testing and final prototyping phase. The plan for the semester is to take the sensor system, mounting system, electrical circuit, and program developed and work them into a prototyped extruder assembly that can be mounted to the LulzBot taz in place of its typical extruder head where it is then able to be tested and operate as planned.

For the upcoming week there are a few things that I personally plan to do to help us progress towards our goal which are as follows:

- Download and set up the Arduino IDE so that I can work with the program to help me understand how it exactly used the input from the sensor and the input stepper motor signal to create a new stepper motor signal to control the rate of extrusion based on the measurements of the filament. The specific parts of the program I will be looking at is the analogueread() function to get a better understanding of how the Arduino uses ADC(analog to digital conversion) to understand the signal coming from the sensor. Additionally, will be looking ant how it them used this data to determine the needed changes to stepper motor signal.

- I will also be looking into the way in which the sensor itself interfaces with the Arduino to make sure that the sensitivity and accuracy of the system is not being hindered by the way in which it is currently connected. Currently the voltage output of the sensor is directly wired to the analog input pin of the Arduino.

- lastly, potentially not going to be got to this week, I want to organize the collection of parts and pieces that are within the projects drawer so that we can better utilize the space and be more organized.