Spring 2025 Filament Flip-Flop (FFF)

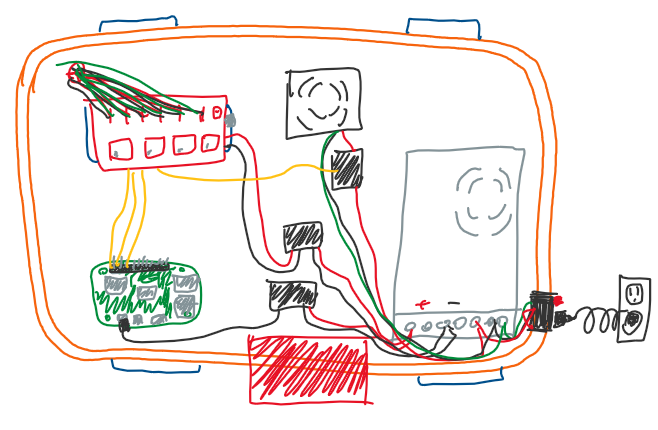

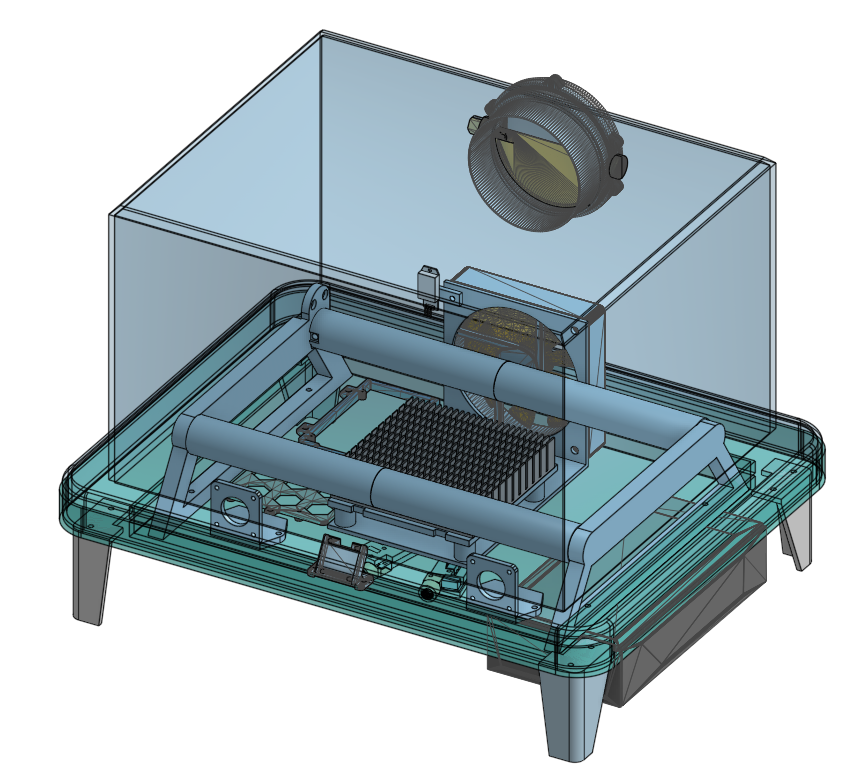

Project Update 1/23/2025: We have so far been very successful with our semester goals for this project. Major things we learned from the fall semester is the need to improve our control system, need to improve heating power, and need to improve the filament stands. This semester we are aiming to achieve printing capabilities with printers. This requires a verity of steps to reach an acceptable state for this. We want to expand to support to 4 rolls, improve the rollers for individual control, expand the heating system, improve our wiring diagram and power system, and improve overall rigidity and interface of the whole system.

Sub Update 1/26/2025: This week I also started work on the Proto-Dash competition. The challenge is to design and build a cheap plant watering and nutrients management system that can scale to some degree. The team meetup this last Friday and determined that we want to make a vertically scaling system that uses multiple reservoirs of water and different nutrient solvents, a pump, and solenoids. We are planning to order our thing this Monday so we can get it together by the 2 week dead line.

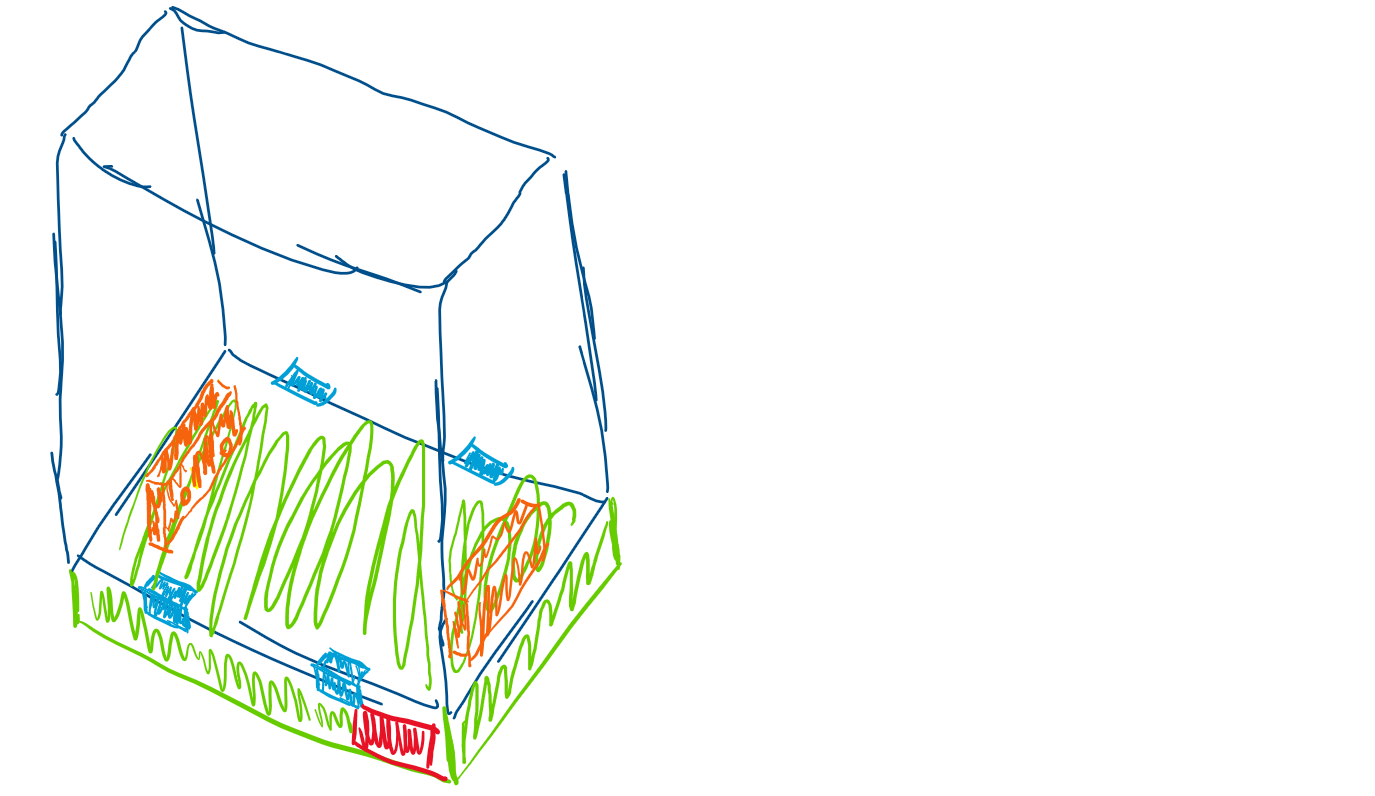

Update 1/31/2025: This week we have Matthew and I have been working on the new stand for the filaments. This new one aims to individually roll the rolls while still allowing them to free spin when feeding the filament. The current idea uses a motor for each roll and a one way bearing to allow the motor to engage the roll while free spinning when no engaging it.

Update 2/3/2025: This last week I have been mainly working on the Proto-Dash project, which is due today at noon. Adam and I were able to design and 3d print the major components and have them ready for the groups assembly. We planned to assemble it yesterday, as our parts were intended to come in. Unfortunately they didn’t arrive. Instead of calling it a quits and hoping they came in in the morning and doing it all before noon, the group worked diligently to find and adapt alternative parts. We were successful in acquiring parts from dismantling an old coffee machine and getting a small ac pump from one of our roommates. With slight changes to the control system and funneling the larger than designed for pump to our smaller tubes, we made a working prototype and made our documentation and video by 4 am.

Update 2/16/2025: This last we we did CDR presentations. In it, our group gave a run down of our current designs and ideas for completing the project. The new roll selector is my main contribution for the moment. The current design takes the simplistic design we had last semester and scales it to improve installation, provide individual roll rewinding, and give the final product a more modular design. This next week I plan to make more modifications to the cad to shift screws to more appropriate locations and to make the design more ridged. I also will be assisting Adam with moving our Arduino control code off the Arduino board and to the Raspberry Pi using Firmata/Pymata. This change aims to allow us to manage the motors and heating systems without them interrupting each other.

Update 3/3/2025: This last week I worked on refining the roll stand modules and I believe I have them close to being done. I also have been working on the new control environment for the Arduino and Raspberry Pi. The current issue we are working on is a problem on boot. Because the Firmata setup only sends info from the Arduino to the Pi when something changes, we don’t really know the current state of the device on boot. To account for it, we are currently going to try a txt/config file that saves the states coastally so that we can pull the last known state of the devices and work from there.

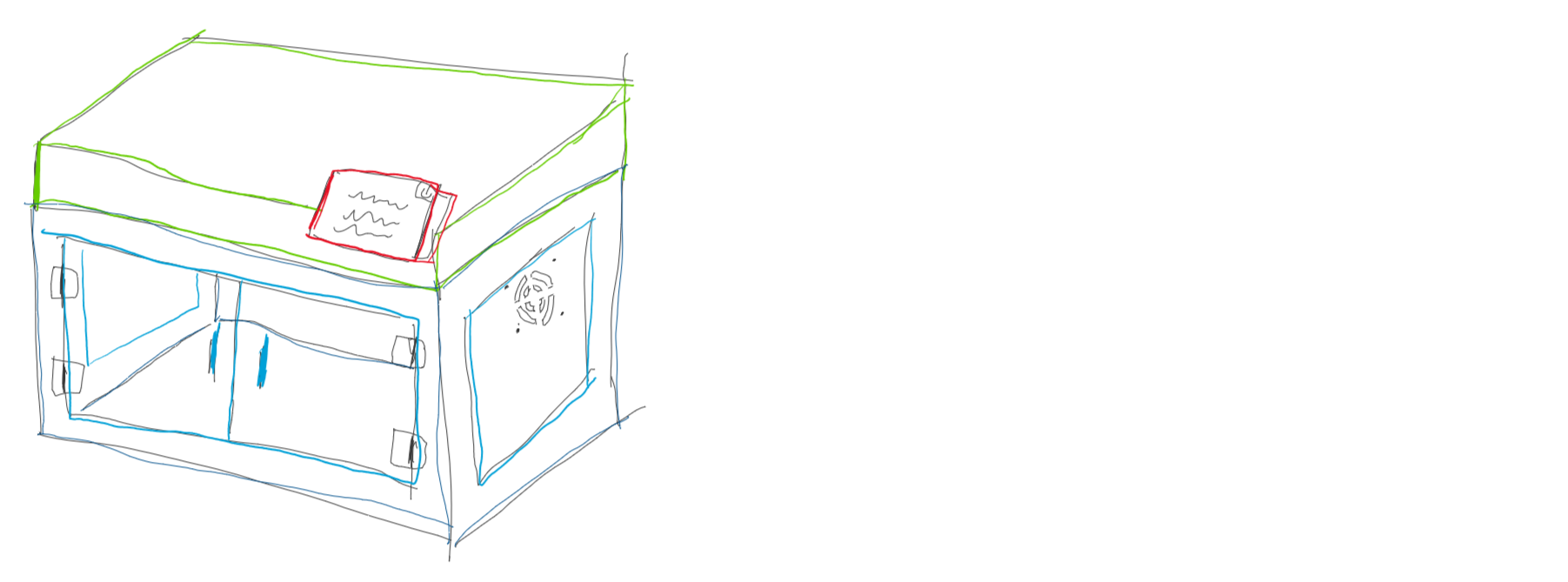

Update 3/9/2025: I plan to continue printing the new roll stand and assist in adapting our control code over to the new system. As a group as a whole, we are getting the new electronics box designed and ready to be printed in sections. We aim to have the new physical components completed and assembled this week or early the following.

Update 3/16/2025: I have printed the majority of the roller stands and have a few assembled, just waiting on the motors to finish assembling. For the electronics box, I have been helping Brady with finishing the cad and getting it assembled this next week. Working with Adam on the control code, we are having issues with having more than 2 steppers declared in the code. When there are 3 or more steppers, only the first can move and the others can only studder. I am considering moving back to having the code run on just the Arduino again. Swapping back may present issues with running the heating control, but we’ll see if we can get the current system operating this week.

Update 3/23/2025: This last week, the group has made great progress. Adam and I moved away from having the Raspberry Pi control the Arduino with Python code. Instead we returned to straight Arduino code similar to the previous semester but with greater considerations for reducing timing issues and making it run more concurrently. We also have most of the prototype assembled apart from the electronics box. We have all the movement system functioning and aim to refine some controls and hopefully get tests completed this week after the box is completed.

Update 3/30/2025: We almost have everything working. Currently we can swap filaments, retract filaments, feed filaments, maintain a temperature to dry the filaments, and control a printer. The issue Adam and I are working on is the Octoprint custom commands plug in. It is currently failing to run our python and shell scrips that initiate a filament swap when the tool change command occurs in the 3d printing g-code. Hopefully we can find the source of the issue before our presentation. Beside that, the project looks great and has really come together into a decent looking device.

Update 4/6/2025: This last we we had our project review and were able to complete all of our fundamental requirements. Early in the week we completed the entire assembly, control code, and did our first full test. We were able to successfully print but with a few slicer, mechanical, and code issues. The first slicer issue is that when the filament was swapped, the change didn’t always fully engage the new filament or fully purge the previous when continuing the print. We believe we have fixed these issues mostly by expanding our printer profile to better match the test printer and also moving to newer slicing software. The mechanical issue we have is that sometimes the buffer system’s spring strength is too week to push the filament with enough pressure to engage with the printer’s extruder. We are trying different springs and buffer sizes to accommodate this. The code issue we have in the Raspberry Pi is failure to auto run our background python script for managing filament deployment. We plan to test adding a custom service file that runs the script aimed to start the script whenever an instance of it isn’t running. So overall, we have achieved the goal of the project beside the build and use directions but aim to smooth out or mitigate current issues so that FFF is more reliable and a competing option for multilateral printing.

Update 4/13/2025: This past week we continued working on the reliability of the system and testing different strength settings with springs and currents. The main reliability issue we still have is the 3d printer’s extruder not grabbing onto the filament when a filament change occurs. This might just be an issue with the printer not being very compatible with the system. We likely won’t be able to solve this issue before I graduate, but I plan on building one of these systems myself and work on improving it. This week we also worked a lot on our project report and are aiming to provide step-by-step instruction on building the system. This next week we need to finish the wiring directions, slicer setup, and operation directions.

Update 4/18/2025: This last week Adam and I worked on our capstone presentation of the project and what our contributions are. The presentation yesterday went without any major mistakes. We did run over our time unfortunately by a few minutes. Next week we will have to continue working on the report and have it complete by Friday.

Fall 2024 Filament Flip-Flop (FFF)

Project Update 9/6/2024: This week we worked on our project spec for this semester. With the project parted into 3 parts we separated tasks between team members based one interests, previous experience, and related tasks. We are currently working on a list of parts to order next week or the week after.

Project Update 9/13/2024: This week we got our spec back and made the suggested changes and made sure to do it with the updated format. We continued discussions in the group to build a consensus on the parts we may need to begin and how we plan to move forward. We will be ordering parts this Friday or early next week.

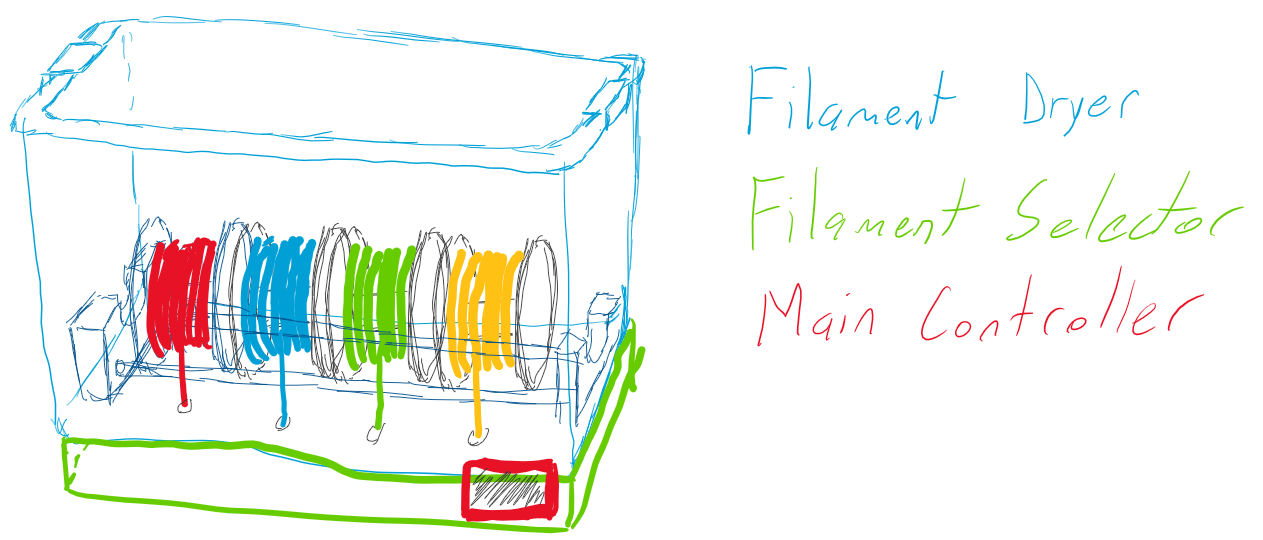

Project Update 9/20/2024: This week the group worked together on creating slides that overviewed the project to present to the other teams in OSHE. Adam and I also placed online orders for a variety of parts and used the P-card to purchase a tote from Walmart. Right now we are getting the team setup to start CAD on the filament dryer using Fusion 360.

Here is another mockup of our current idea for the project: The main difference with this one is the tote being used upside down to make the inside more accessible.

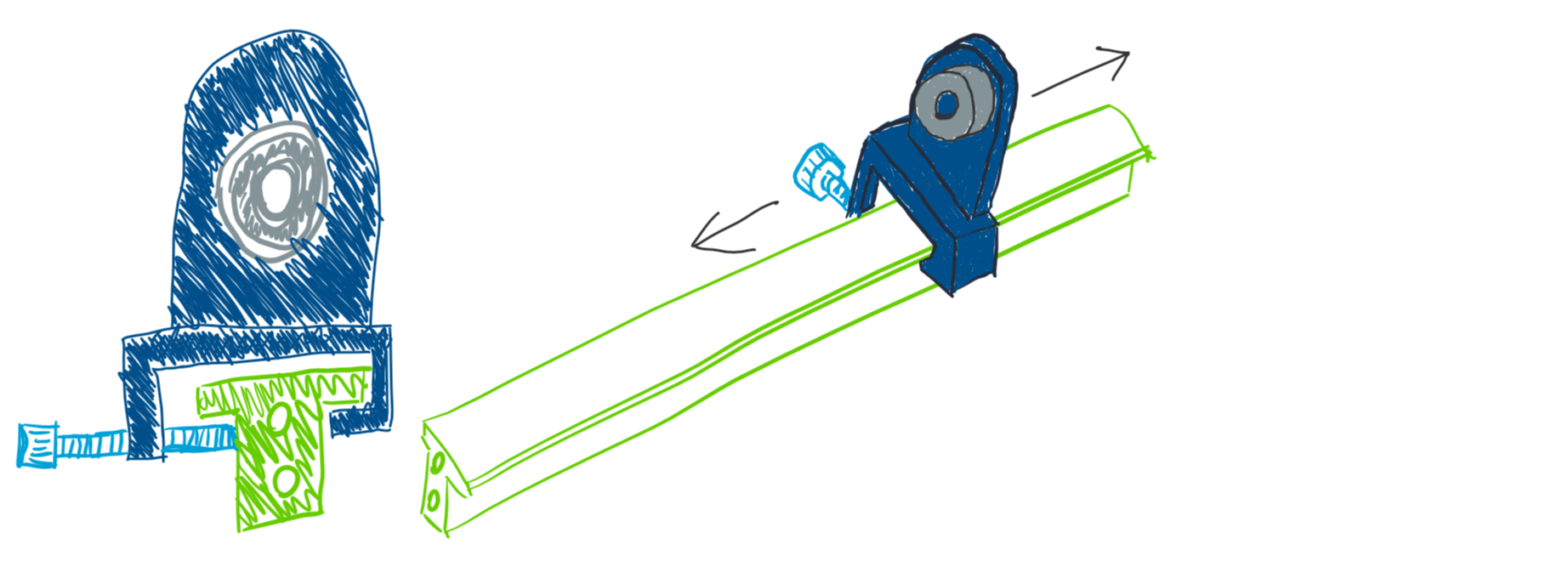

Project Update 9/29/2024: We are moving over to Onshape for CAD as the free Fusion 360 licenses don’t allow for a editable shared folder between a team. I have also worked on an idea for holding the rolls. Because some rolls are different widths I wanted to come up with something adjustable. The bellow image illustrates my idea. I took inspiration from din rails and wanted to make a mostly 3d printable rail with mountable bearings for the roll’s walls to roll on. On other notes, our parts weren’t in this last week but hopefully they arrive today or tomorrow so we can complete a rough cad of the dryer before our CDR.

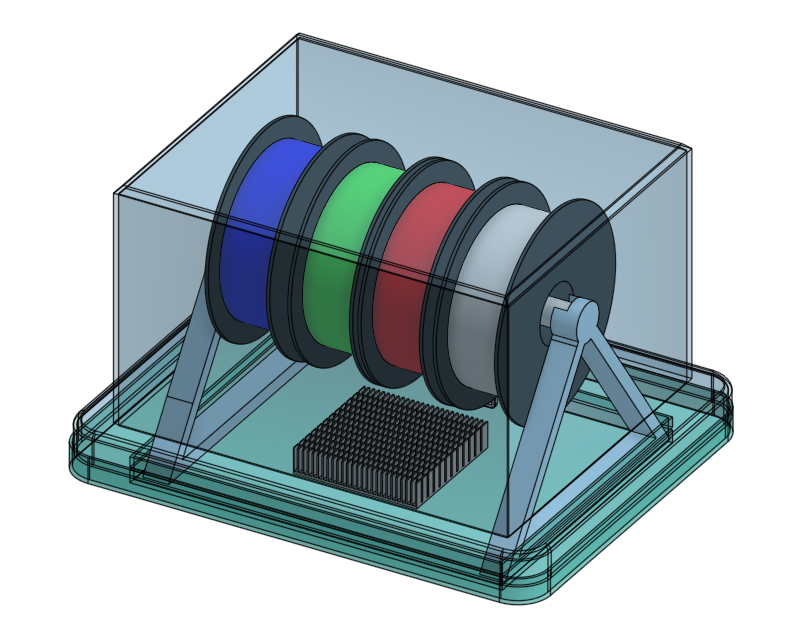

Project Update 10/3/2024: We have a good amount of the cad done. We decided against the idea I had and are currently going with a simpler one. Here is the current assembly.

Project Update 10/31/2024: Over the last few weeks we have been working on getting the electronic systems made. The main change we have made from the plan we set at the start of the semester was to move to a ramps/Arduino max board. This is because Dr. Shane gave feedback on our plan of modifying Marlin software, state that it may be more time efficient to code from the ground up as we would likely struggle modifying Marlin at the degree we needed. Now we have an Arduino code file that displays info from our sensors such as our filament detectors, temp sensor, and humidity sensor. We need to work on stepper control as we have not successfully controlled them yet. CAD wise, we have modified the filament stands to use a 66 rpm motor and move the filament rolls. This next week I need to print out these stands and design a fan duct that can open and close for the humidity control.

Project Update 11/15/2024: This past weeks we have been working divalently to piece our different components together and getting the backbone code for running the components. This morning we got the communication between our Raspberry Pi and Arduino operating and causing the Arduino to change the state of the filament system. With this working, this prototype is operational. The video bellow demonstrates it.

Spring 2024 BREAD BUNS

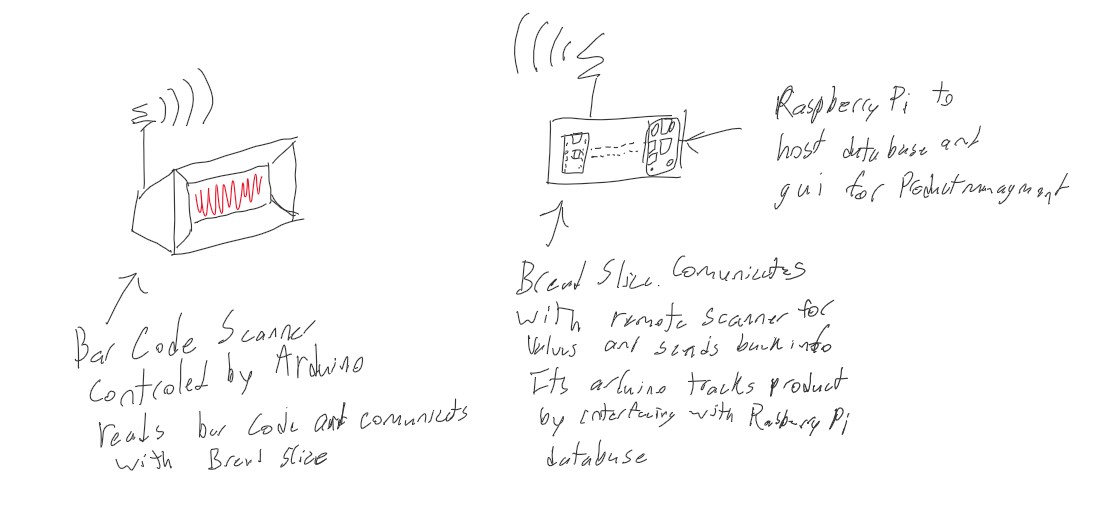

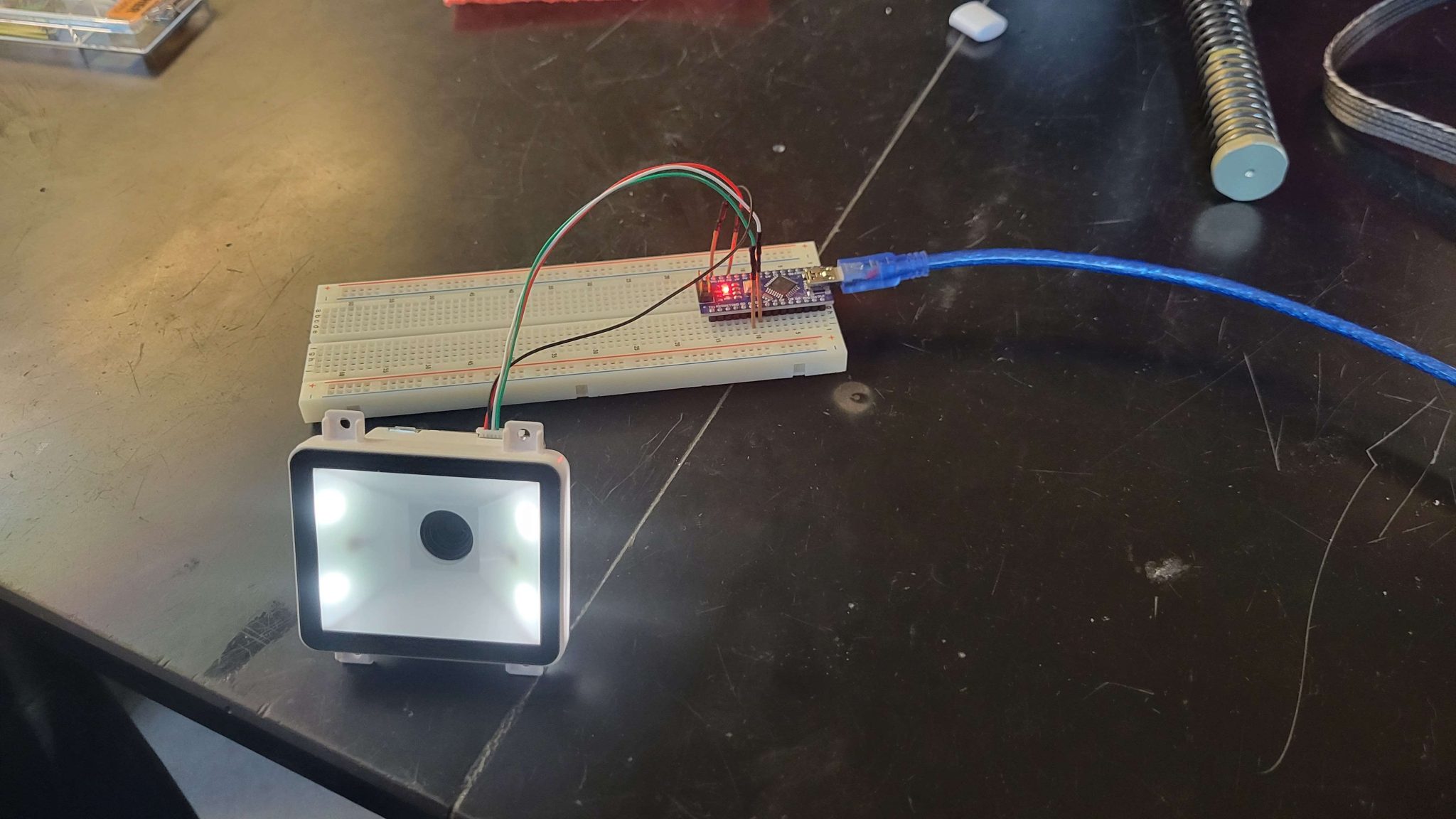

Project Update 1/27/2024: This week the group discussed and ordered components to begin work on one of the member’s (Nic’s) capstone project: BREAD BUNS, a barcode scanning deceive with the goal of tracking the movement of products in a plant environment. In the following weeks we aim to begin testing the bar code scanner that we ordered and begin the design of the remote scanner.

Project Update 2/3/2024: The parts that we ordered last week came in. The design of a prototype (breadboard) has been started and other projects have been looked into. We have found a project using a similar scanner to ours and plan to learn more about their project and perhaps incorporate some of their ideas. This next week we aim to begin the assembly of a bread board and coding the remote scanner’s Arduino.

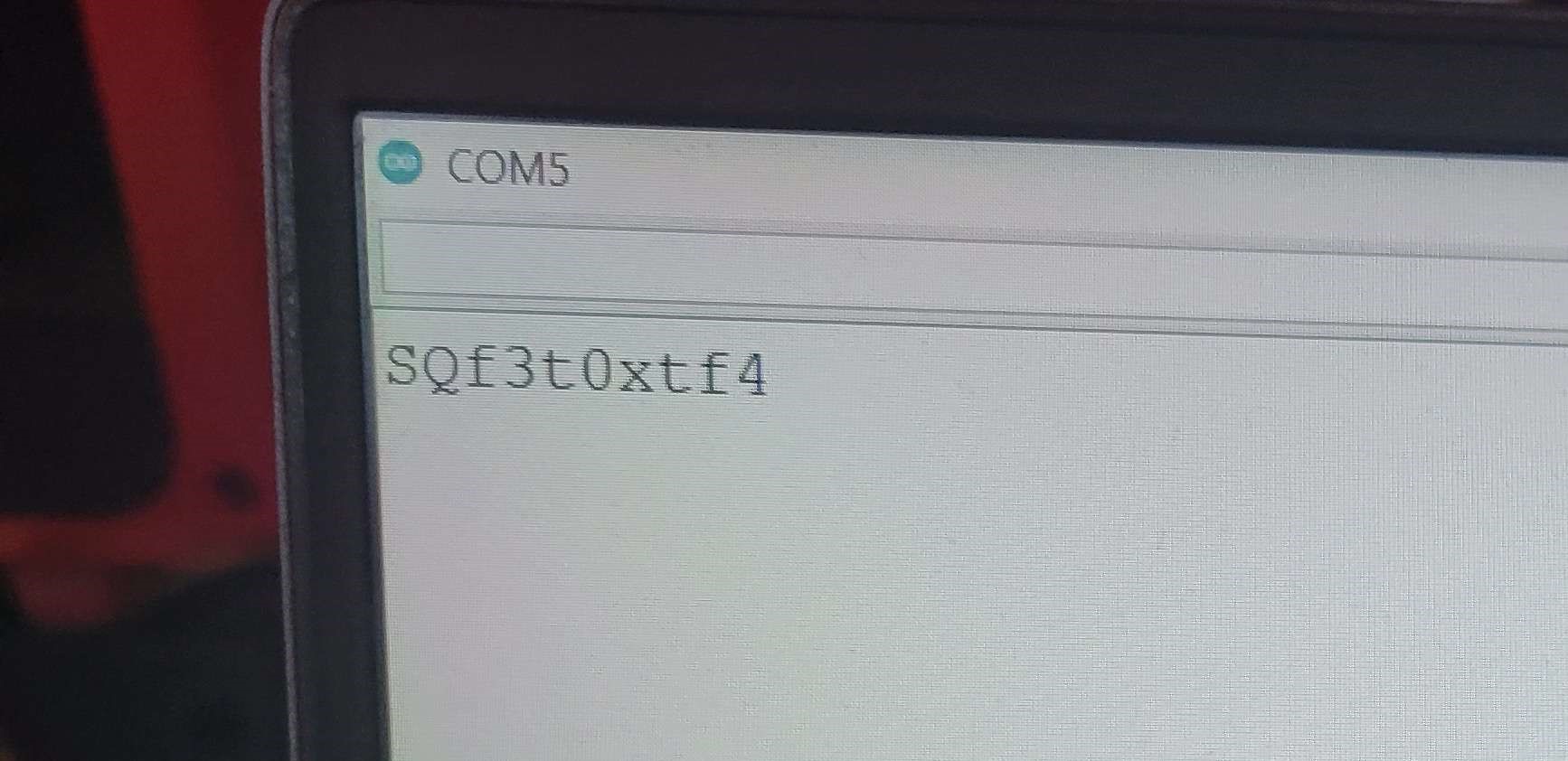

Project Update 2/10/2024: This week we successfully able to read both bar codes and qr codes with our scanner. So moving forward, we need to start work on the slice that will communicate to the remote scanner as well as the remote device’s radio communication. As a group we decided that Adam and I will work on the slice and remote while Nic will begin work on the data base/raspberry pi.

Project Update 2/17/2024: This week, we began work on our CDR and worked on the radio module of the scanner. We were not super successful with establishing communication but believe we are getting there. This next week, we will be making our slide for our CDR and aim to section up our slides so that each critical area can be reviewed individually. After our slides, we hope to continue work on the radio communication and be able to send values over the connection. I may also add the display to the scanner to display read values.

Project Update 2/23/2024: This week we did our CDR and got some interesting feedback. Apparently the radio modules we are using may be capable of operating without the Arduino nano if we don’t include extra features on the remote scanner. We are considering testing without the Arduino and (if it goes well) making a design without the Arduino. We are likely still going to make the design with the Arduino as we aim to make a scanner that is capable of displaying the value from the barcode on the device. Having the featured and basic remote scanner may be beneficial to our project. This next week (over spring break), Adam and I will continue our work with the radios and hope to make steps towards our first prototype.

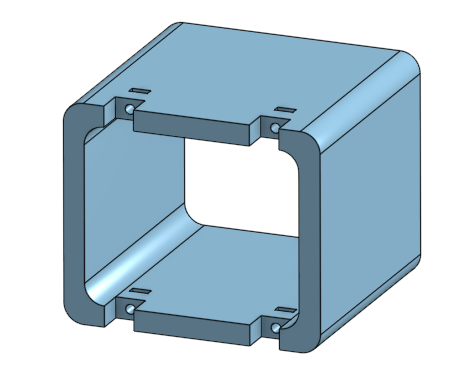

Project Update 3/9/2024: This week we started combining the different components of the project. We have the radio communication between the two Arduinos and are able to send over scanned barcodes. Additional work needs to be done to have the raspberry pi able to send data from the database to the Arduinos, but we should be able to send scanned items to the database. Now, Adam and I will continue development of a prototype pcb and some 3d models to house the scanner.

Project Update 3/16/2024: I now have a prototype model to 3d print so that the prototype scanner can be better visualized and be used as a reference for the pcb size. I recalibrated my 3d printer and got it ready to print again so that I can print the model sometime next week. I also got Kicad downloaded on my computer and I am importing the different components to design the pcb. We also went ahead and ordered ~1in oled screens, usb modules, and a hand held scanner. This next week we hope to complete two pcb prototype boards with and without a usb module to communicate to the actual scanners.

Project Update 3/23/2024: This week I found that the Kicad software had issues with the graphics drives on my computer. I managed to resolve this by swapping out my drivers. also found that additional changes need to be done to my 3d models to account for errors with 3d printing and for additional space for wiring. I will continue working on the pcb and 3d models.

Project Update 3/29/2024: Our new parts came in and we have started work to add the screen to the scanner and add a mounting point on the model. With the usb module, we will test out our hand held scanner as well as the usb port on our existing scanner.

Project Update 4/6/2024: This week we did a verity of tests. We found that the usb module that we were trying to use for the hand held scanner was not able to operate with the current Arduino scanner without major changes to our code. So moving forward we are going to focus more on the working uart scanner. We also found out that we can’t power the radio module off the power of the Arduino as the power needed for max range exceeds the Arduino’s output. This next week Adam and I hope to find and order a suitable battery for the remote scanner and to continue work on our pcbs.

Project Update 4/13/2024: This week we worked to combine all the parts we had completed into a working system. We meetup and finished our report with the details on our current system and our ideas for it. These last two days Adam and I increased the capabilities of our remote communication, increasing our max characters from just 31 to hundreds. Now we are trying to wrap things up. We plan to organize our review process for our check offs and have things ready for next semester.

Project Update 4/20/2024: This I reviewed the proposed projects for next semester and made my vote on what should be done. This week also had the capstone presentations. The majority of them seem to be on track or close to be. As for BREAD BUNS, we are extremely happy with how far we got and Nic expects to be able to finish during the fall semester.

Fall 2023 Project BREAD MOLD

9/23/2023: This week I assisted Growbot getting back to an operational state. I also gave a run down on the project to members of the current Growbot team. For Bread, Nic and I search the available parts in the lab to use for our project and listed out what we were still missing to begin developing our slice “MOLD”. This last Friday we place our order for screens and load cells. This puts our project cost to $17.92.

9/30/2023: This week, Nic and I picked up the parts we ordered last week. With the new parts and the parts from the lab, we began to make the first proto type. This first prototype had the goal to read in a analog value from a load cell. Using an Arduino library and a tutorial, we were successful is reading values. Next week, we plan to print out brackets for our load cells and make adjustments to current code to incorporate the components besides the scale.

10/7/2023: This week Nic and I expanded the prototype to use all 4 of our load cells and constructed a crude weighing scale. Then we started work to add the LCD display and the rotary encoder for the interface.

10/28/2023: Nic and I over the last few week have been working on getting the LCD display working in the project. We have some concerns with it due to the display using I2C communication and the loaf also communicating in I2C as well. If we come to any problems as we move to get it communicating with a loaf, we will refer to the other BREAD team and or BREAD documentation.

11/4/2023: This week we reviewed our code. Updated the comments, changed the organization of the code, and improved the display management. We also began work to have the slice communicating with the BREAD loaf and have gone over the documentation on I2C communication.