Filament Flip Flop (FFF)

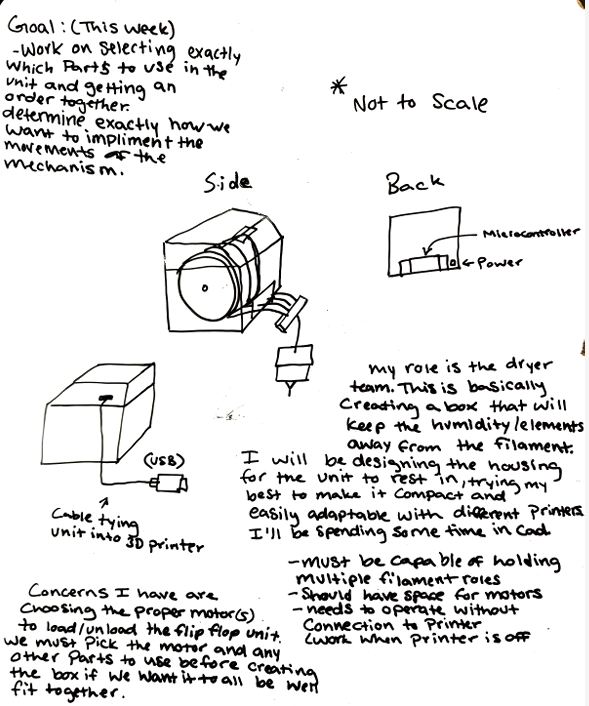

(9/13/2024) This coming week I will be working on designing the general dryer unit for the filament flip-flop unit. This unit should work while the printer is off to ensure that the filament remains in good condition to avoid any problems while printing. I will be working with my team to come up with a list of parts to integrate with the unit and also researching the best way to go about keeping the effects of the elements away.

(9/22/2024)

This week, we primarily worked on the presentation to present to the enterprise and a list of parts/the way certain aspects of our project will be integrated together. Still unsure of how exactly we want to do the extruder portion of the project, we focused in on the external design as we decided how the box will be and decided to change the placement of the clips to the bottom instead of the top of the container. We purchased some parts for the project and will proceed with those likely this coming week.

My goal this week involves deciding the final design for the dryer unit and working on coming up with the design for the filament switcher (extruder portion). A list detailing this goal follows:

- Brainstorm and research dryer unit options to determine which one best matches with the description in our plan

- Brainstorm and research options for the extruder/switcher to determine the best course of action for implementing that

- Figure out which parts are needed for the switching unit and order parts for that or at least narrow down the list to order parts for this unit this next week.

Concerns for the coming week

- Coming up with the switching unit is going to be a pretty big task, it is likely that researching this unit will take longer than this week as we have other pending tasks at hand. It is important that we pick a design that will not clog or cause issues down the line.

(9/29/2024)

This week was a chaotic week with all the events of career fair so it was hard to get all of the goals accomplished. We started a shared drive for CAD files and finalized and ordered some more parts. Since we are awaiting parts to come in, a delay has taken place. Originally we chose to use fusion 360 for CAD but ended up going with onshape instead as it was easier to share files. We are still pondering the best way to go about the switching unit, hopefully a consensus will be made in the next meeting. Goals for this week rely heavily on parts coming in. Once parts come in, we can measure them and create the unit to scale with precise features in onshape. I will be working in onshape on the dryer unit. Collectively, we will be coming up with slides and preparing for CDR.

(10/03/2024)

We made some modifications to our plan for the device. We received some input during CDR that lead us to decide on a Ramps 1.4 board in correspondence with an arduino for the sensor/motor controller board(s). We are waiting on the Ramps board to come in and some of our teammates are working on programming a plug in to interact with octoprint.

(11/01/2024)

After some more thought and modeling in CAD, we came up with a new design for the filament holder and started the print for that. We got the LCD screen hooked up on the device to display temperature stats. The filament rollers are now printed and assembled as well.

11/15/2024

We have been working on coming up with a bowden connector for the filament to flow through and be detected while in this unit. This piece will be how the device determines if there is filament in that tube and determines which roll is being used. We have made a lot of versions of this but hopefully have settled on one at last. We are working on printing that to test it out and see how it works.

12/01/2024

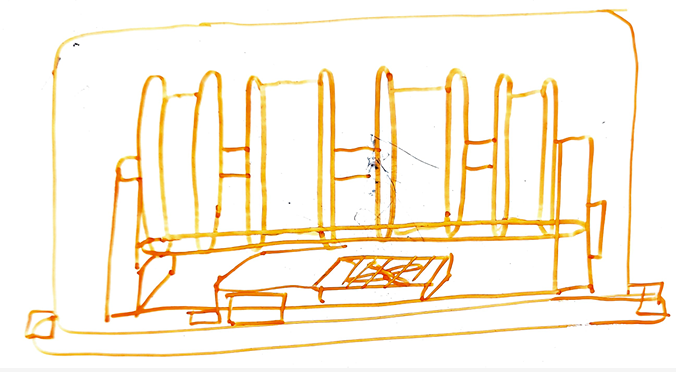

We have assembled the device and it is functioning, a few things just need to be worked out. Currently the device utilizes only 2 rolls of filament but we believe it will be easy to expand this to 4 rolls in the future (likely next semester). One issue we have noticed is how long it takes for the unit to heat up, this will also likely be an adjustment for next semester.

1/17/2025

As a team, we have gone over what we would like to work on this semester and divided up roles. I will mostly be on the electrical portion this semester. We have established project goals and agreed upon the things that need to be tampered with this semester. We would like to get a better heating element, be able to switch the device on and off instead of plugging in and unplugging it, expand the capacity from 2 rolls of filament to 4 rolls, and rework the wiring configuration among other things.

1/24/2025

Not a whole lot has occurred this week as we had a presentation to give and were therefore working on that during out meeting time. We ordered some more parts and once those come in we will be modifying the device. We decided on a new heater which is more like a space heater than the 3D-printer bed unit and heat sink we were using in the previous edition of the filament flip flop unit. I will be wiring in the switch for power control likely this coming week and we will go to work expanding capacity for the filament rolls which mostly will be printing and assembling more parts and putting those all into the assembly (then of course modifying the program a little bit).

2/3/2025

The team worked on creating more mounts for the devices and 3D printing those to try out. Specifically, a mount for the LCD and raspberry pi, we will continue to move forward with the modeling phase and testing of the parts as we move forward. Ideally, we would like to make the enclosure more concise and better contained throughout this process.

2/10/2025

We are redesigning some more parts still and testing those out with the rest, a lot of things can be expanded upon to make the device more efficient. A new roll selector is in the making and a little more work on the programming is also needed at this point in time.

2/17/2025

We ordered some more parts this week, a new heater and a dimmer. Working on some more part designs still and integrating those all together.

3/3/25

We ordered more new parts: motors for the filament rollers. Our team has been troubleshooting code a lot this semester so that has taken up the bulk of our time thus far. I have started redesigning the wiring diagram for our device as the old one was quite disorganized and difficult to follow.

3/10/2025

We are starting to put all the new parts together officially as the deadline is quickly approaching, they work individually but some issues seem to be arising as the enclosure is all put together. I am working on finishing up the wiring diagram.

3/17/2025

I was out of town this week so was unable to help out much as a result. My team is working on printing some more parts and redesigning a few holes on parts where the components and their mounting brackets do not align due to a few measurement errors. We will be putting it all together this next week and making sure everything works for the final checkoff. We worked on our presentation as the team presented to the class this week.

3/24/2025

We have been putting together the device again this week as we have slowly dismantled it in the remodeling process. We are cleaning up the wiring and in the final stretch of grind time before the final project check off on Monday. I will be working on redesigning our slides for the presentation and have submitted a social media post for our team as a result of being absent for the presentation last week during class. There are 2 parts in particular that are not working quite as we expected, one is unimportant and just there for looks so not a big deal really (but this is easily reprintable). The other is the boden connector. We found that the enclosure was a little short for this to stand flush with the lid of the tote on top of that. This likely is not a big deal as long as it runs properly when the entire system is running. If this is not the case, we can simply create a trim layer that will provide that couple of millimeter gap needed to allow for the filament to move freely with no restrictions. This is to be established as we finish up the project this week.

3/31/2025

Some issues that arose in the final application of the project:

- Failed Prints (this was just due to the printer used to implement the demonstration, the extruder clogged)

- The tight fitting electronics box does not make for easy dismantling (this however should not be an issue as you should not need to tamper with this)

- The instructions are not super straight forward for a new user but this can be fixed by mounting instructions on the box

- Cura is not made to use multiple colors so it makes it a little more complex to implement but is still doable

We will be working on the final report this week and updating the social media post to contain a video of the unit using multiple colors in a single print. Overall, the project is complete and meets all requirements we created at the starting stages of this adventure.

3/31/2025

We are working on getting some pictures and a good video of the FFF unit working while a printer is using it considering during our final presentation it was malfunctioning since the printer’s extruder kept getting clogged. Luckily, this had nothing to do with the FFF unit itself. We will be working on the report this next week or 2.

4/7/2025

We are working on finishing up the report which is due in a few days. We are mostly finished with it, just need to find a time to get the team together again and grab a few more pictures and things for the report.

Project X

12/6/2025

We have not really had to keep track of our worklogs this semester, so this is all going to be condensed into one section. Project X is also known as the Chatter Cuff – a name that may or may not replace the project next semester. The chatter Cuff is my capstone project. Essentially, I came up with this design while skiing. My friends and I like to be able to communicate but find it rather hard to do so while out on the slopes. In order to negate this issue, we moved to walkie talkies last year, but it is still difficult to find cheap walkie talkies that will comfortably fit while working properly. The earpiece on the one I have becomes uncomfortable quickly, and it is rather difficult to find the transmit button on the cable with gloves on, it almost always gets trapped somewhere in my gator.

The scope of this project is to create a cuff that is easily accessible with gloves on. For semester one, we chose to keep thins simple, being able to demonstrate that we are able to create a walkie talkie device. The project deliverables are as follows:

- The device is capable of transmission/reception

- The device has an adjustable volume feature

- Contains a power on/off feature

- Attaches to Wrist/Arm/Hand

- Device is batter opperated

- Frequency utilized operates within legal limits

- Light-weight device

- Device has the ability to play audio

- Project aligns with open source hardware constraints

- Battery life up to 6 hours

- Buttons are easily accessible

- LED lights up when powered on

As you can see, all of these deliverables are easily obtainable this semester. Next semester, we seek to be able to condense the device down to one PCB and troubleshoot any bugs.

Semester 1 Overview:

We chose to utilize an ESP-32 module as this is an easily obtainable radio for most hobbyists. The rest of the components fell in line with the help of some research. We ended up identifying an ESP-32 module, amplifier, 100-ohm resistor (gain), microphone module, switch, 4 buttons, and a battery to create the prototypes on a breadboard. We opted not to go with a linear regulator as the ESP module already regulated the power. We breadboarded up 2 prototypes for testing purposes.

We utilized ESPNOW with the Arduino since this was a pretty straight forward package, with many favorable options. We began with a range of about 200 yards before also applying a long range mode to the device. Although the range can be decent, any disturbances between the walkie talkies can cause interference, this is something we are seeking to negate next semester.

Creating a housing for the device proved to be rather difficult with all the connections, there was no good way to keep all the components in the device without threading the wires through holes in the housing. This made assembly a bit of a nightmare, but doable overall. We ended up with a rather large cuff that sits on the forearm and is attached with Velcro straps. A wire comes off the device with a button attached to an elastic band to go around the index finger of the wearer’s glove. This button is the transmit button.

We were able to get a condensed PCB designed and ordered this semester so hopefully we can hit the ground running next semester. There were some ordering hiccups with components, so we will need to wait for those to come in the first week of next semester still unfortunately. The condensed PCB will be about 3-4 inches by 1-2 inches. This is not quite watch size as we were thinking it could be, but we kept all the components on the top side of the PCB and used primarily 0805 parts so that they are easily solderable. Some of the ICs selected are rather small so we did also purchase a stencil with the PCBs just in case they are not hand solderable. Looking back, it is likely that we will search for a new component in place of those small ICs in order to negate the need for a reflow oven and keep this project fully open source. In the event that we can not make this change, we will verify that a heat gun can provide the necessary environment for the maker to assemble the PCBs.

Above all, we would like to configure a way to pair a Bluetooth earbud with the device instead of either a wired option or the speaker. The speaker is alright, but it would be nice if the speaker was closer to the ear for easy communication. It might be nice to be able to pair and earbud that contains a microphone as we could eliminate 2 components on the PCB and ease communication all the more. With the new PCB, we did utilize the ESP module with an attachable antenna with the hope that we will be able to gain a greater distance and less interference with this idea.