Week 14 – Spring 25

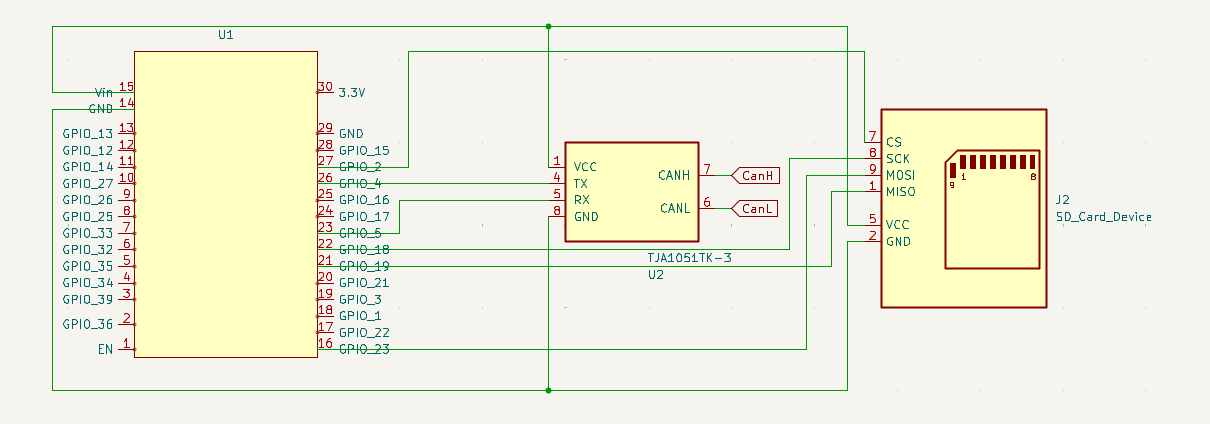

This week I put in some time finalizing the PCB for the project report and have worked on finishing my portion of our final report. There isn’t anything else to do going forward as this is the end of the Open Mobility project.

Week 13 – Spring 25

This week was just project report draft time. I’m in charge of finalizing the control slice PCB as one of the idle goals and to write down any information regarding the PCB, over current, and undervoltage protection for the report draft. Following this week will be the final version of the report to be written for the Open Mobility project completion.

Week 12 – Spring 25

Project check offs were this week. The final touches were put into the board to get it ready. I soldered together the communications slice power connections and Joel finished the pin connections. After the slices were soldered together the final project was put together for check offs. However, there was an issue with the voltage regulator we used that was causing strong transients and damaging the esp32. This was a lasting issue through the first round of check offs. Following this we made adjustments and modified our design till it was fully functional for a second round of check offs. Going forwarded the final report needs to be drafted and put together, but the project has reached it’s final stages.

Week 11 – Spring 25

This week the final schematics were drafted up and prepared for soldering on the protoboards. Tyler and I did the schematic designs that connected each previously drafted part onto one board. With everything printed and prepped it just has to be put together in the final assembly by Thursday when we go through the design checklist. This following week I will be present for the final assembly and help make sure everything goes well. I will also be familiarizing myself with all the other aspects of the project to be better prepared for final design check off.

Week 10 – Spring 25

Lot of work was done this week in preparation for final assembly next week. Alex has been working on ironing out any errors on the battery voltage regulation/monitoring circuit while Malachi got the IC ordered for voltage regulation on the microcontroller end. During this week a lot of the design finalizations were made on the schematic end. Going into next week Tyler and I will need to prepare the schematic that connects every individual circuit onto a protoboard. Following a prepared design we will solder the final assembly together in order to be used with the undercarriage Joel is designing for the final product.

Week 9 – Spring 25

This week we had some of the components arrive so work can begin on putting the final project together and the undercarriage assembly. They didn’t arrive until later on in the week so not much work was able to be done. Next week should see a lot of progress once there is a direction established following our Tuesday meeting. The components arriving have been a hold up as the theoretical work has been done, all that remains is the final assembly and quality testing before a final presentation can be made.

Week 8 – Spring 25

Following CDR we’re still waiting on some components to arrive so it’s hard to finish up. The communications/microcontroller groups on the project made good work on communication between the transceiver and the motor. The duty cycle is able to be read and variably control the speed based on the value. The overall scope of the project is looking very good, its just missing the protection components that we need to arrive. This could be problematic as the week 12 deadline approaches but the parts were ordered with hopefully plenty of time in advance.

Week 7 – Spring 25

This week had CDR and a bit more work after that to lead into spring break. A lot of the time was put into preparing the presentation and attending Critical Design Review. In the latter half of the week, different components were ordered so they would have more time to arrive throughout the end of the semester and spring break. This allows us to finalize a PCB design going forward as the components for the project have been mapped out and prepared. With a finalized PCB design, the final project can be assembled. That’s a bit of a later thought as we still need to get the PCB milled and everything locked into place. This week I will be working with Tyler to get the finalized circuit designed and then work with Alex on the last touches. Following that, we will have to wait for our last components to make it before final assembly begins.

Week 5 – Spring 25

This past week Tyler and I looked through different power switches to buy. We found 7 different options but are struggling to find options in a valid price range that can handle our needs. In addition we’ve been looking into fuse options and are almost set on ordering one that is surface mount. This will take away from the ease of modularity but will be enough of a price benefit to justify it. The under voltage method is being researched as we’re going to purchase an IC. At the moment different chips are just being compared before we make a purchase before CDR. This leads into next weeks tasks as we have to prepare for CDR. Prior to presentations we want all of our orders sent in and to work with the whole team to develop a schematic that allows for battery voltage monitoring with the microcontroller systems.

Week 3 – Spring 25

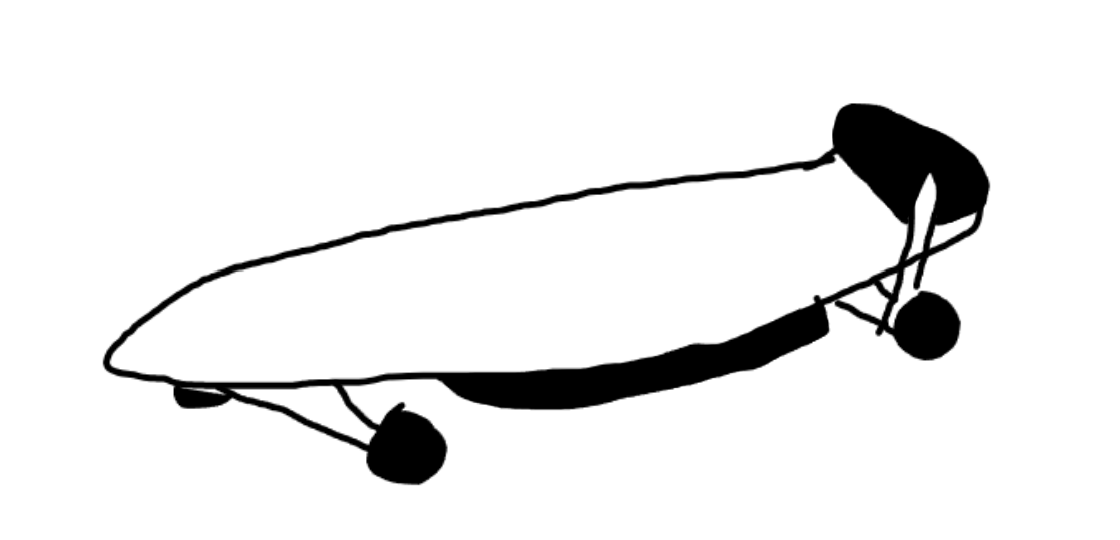

This past week saw the set up for the project going forth. The semester goals were laid out and how we were going to approach them was discussed. This semester will function a lot more week by week rather than having assigned tasks to do across the whole semester. By going this way we are aiming to reduce down time and have a more efficient semester. This week I need to research alternative under voltage protection to see if there should be any changes and work with Alex and Tyler to begin some kind of larger scale circuit design. This will be used to set up ESP32 connections and to use them as a BMS system. ESP32’s will be used to monitor the battery output, health, and functionality. Following it might be challenging to have a good design circuit design made but it is something that will be worked on among multiple people across the following weeks. I’m imagining the final project to look like this. It will have a bottom carriage with a top mounted motor. This is mainly due to our motor being large so having it mounted under would be very challenging.

Week 5

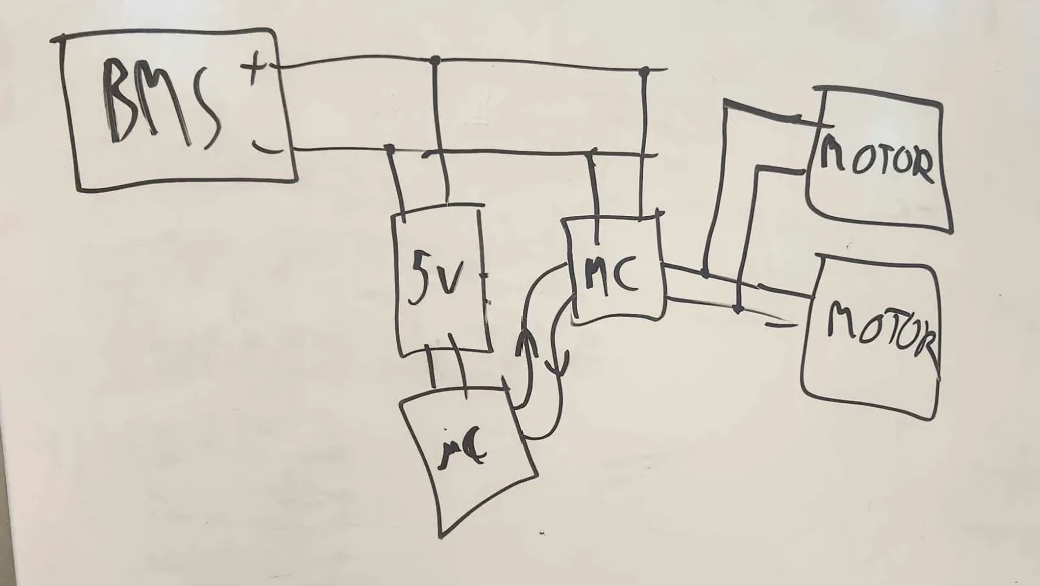

This week a lot of progress was made in preparation for part ordering. We discussed what method we would use to step down the battery for the control slice and the motor slice. This led to the idea of ordering a dedicated buck converter chip for each necessary voltage level. We met with the ATX power supply group to get a better understanding on how to design these systems with different voltage rails. They helped us decide what methods we should use to achieve our design and gave some inspiration in the block design. Following this week, there will be a meeting on Monday to order parts to begin assembly. Once the final parts are decided on, a circuit design can be finalized in preparation for CDR on Thursday. I was able to come up with this block diagram for the project.

Week 4

This week the battery slice subgroup of the Open Mobility project had a meeting to further discuss the battery design. The choice was in between buying individual battery cells or a pre made pack. We came to the conclusion that a premade pack would be worth the slight increase in price so we could focus our attention to another aspect of the board design. Following this, we will need to email both MBoards and DIYboards to see what comes with the BMS products. In addition, the battery slice will be focusing on designing rails necessary for communications function and motor function to better prepare for ordering parts.

WEEK 3

This week I researched 2 boards, looking specifically for the batteries used. I’m trying to look at what other successful boards use for batteries and motors so we can find effective components in our design. Following our meeting Monday we will have a completed performance envelope and done more research to prepare for the presentation Thursday.