week 14 concerns:

- As long as we do the project spec I should be fine for OSHE

week 14 to do:

- We still need to finish the project spec.

week 13 update:

- We had a meeting with our team sponsor to go over what we did this semester. Very similar to the design checkoff that we did with Shane.

- Also those in second semester capstone had to do their final presentations in front of the class.

- I meet with the OSHE website dev team and we went over what we needed to finish up this semester, and what I needed to learn for next semester. I’ve decided to do a bi-weekly meeting to help facilitate work on the website being done in a timely manor.

week 13 concerns:

- im pretty sure this week will be very chill, all we need to do is work on the project report.

week 13 to do:

- meet with the website dev team on Wednesday.

- Work on the project report.

week 12 update:

- This week we had our final design check off with Shane. HE gave us an 85, we lost points on the pH sensor, the physical E-stop button, and the pressure slice. Neither the pH sensor or the E-stop had been tested all semester leading to both of them failing. While Shane said that because there was no physical pressure slice to be tested we hadn’t fully completed what we set out to do in our project spec.

- I also set up a meeting with the OSHE website group to discuss what we need to do by the end of the semester.

week 12 concerns:

- I am unsure that our team will be able to finish all of out goals by Tuesday, which is when our checkoff with Shane is. I am also unsure of the current status of the pressure slice design as I have not seen one of my teammates, who was in charge of the slice desgin, for a few weeks at this point.

- I know That I personally have other exams going on this week, and I’m sure others on the team are also busy, so I’m not sure how much time I can realistically dedicate to this project over the weekend.

week 12 to do:

- Having successfully developed a method to test the pressure transducer, and executed said method to prove the transducer works as expected I have accomplished my goals for the pressure slice. Now I need to assist in completing other goals, and potentially even working on the idle goals.

- the final checkoff with Shane is this week and our team still has a few unfinished goals. We got together and planned to spend the weekend working on finishing up the last few goals.

week 11 update:

- This week me and my teammate meet up after class to go and try to test the pressure transducer at the local air pump. However we encountered some major issues, namely the air pump isnt out yet due to it still being freezing cold outside.

- We then decided to simply utilize the air chunk to blow into the pressure transductor. simply applying this amount of pressure we could watch the output change, if only just a little bit. Josh then made a program that would print out the equivalent PSI repeatedly so we could track the pressure change automatically.

week 10 concerns:

- we are approaching the endo f the semester. Our team has placed the order for the pressure slice’s PCB, and has developed a test for the pressure transducer, thus meeting our requirements set forth in the project spec at the start of the semester.

- I need the parts to ship to test the pressure transducer, if the parts don’t ship I wont have much to put on the slides for the upcoming presentation, and we wont have tested the pressure transducer meaning we wont have accomplished the goals in the project spec.

- I’m also just stressed out from having 4 major assignments and two exams this week, and two more exams next week. The presentation this week doesn’t help either.

week 10 to do:

- in the upcoming week I need to test the pressure transducer using the circuit designed by my teammates to ensure the transducers functionality. IT shouldn’t be too hard as I simply need to fit the parts together and measure the air pressure using an air pump.

- Our team’s weekly presentation is this Thursday so we need to go through and add all of the stuff we’ve done to our previous slides in preparation for the upcoming presentation.

week 9 update:

- This I had planed to stop by Shane’s office to order the parts, however he was busy all day, until late in the evening so I had to come back Tuesday. Tuesday morning around 9-10AM I went into Shane’s office and managed to order the necessary parts, they should be here next Monday.

- I discovered that using the 1/8″ npt female to 1/4″ npt male threaded adaptor that I ordered we should be able to swap the current pressure gauge with our electronic pressure transducer without having to add any new parts, or causing any issues with the current design of the bio reactor. I probably need to buy some Teflon tape, but that should be less than a dollar at Walmart.

week 9 concerns:

- Most of what I need to do in the upcoming week depends on my fellow students and the progress they have made. If the circuit hasn’t been designed, or the slice kiCAD file hasn’t been made then we will be far behind schedule for the upcoming weeks.

week 9 to do:

- this week I need to order the necessary parts for the pressure slice, including the 1/8″ npt female to 1/4″ npt male threaded adaptor that I spent probably 3-4 hours looking for. \

- I also need to meet with my team to confirm the circuit for testing the pressure transducer has been made so we can test it when the parts arrive.

- I plan to spend time in the GLRC lab looking over the bioreactor to determin the best method for replacing the current pressure gauge with our new pressure transducer

week 8 update:

- this week I spent hours searching the local hardware stores for a 1/8″ npt female to 1/4″ npt male threaded adaptor with no luck. I ended up having to look online to order the part, and a few other things for the pressure slice, however I need to wait till Monday to order the parts at Shan’s office.

- I also spent time researching ways to test the pressure transducer, and landed on the idea to use the air pump at a local gas station to provide an constant psi output to accurately gauge if the pressure transducer works.

Week 8 concerns:

- I don’t know if the pressure transductor arrived over break, so any testing might have to be delayed until its arrival.

- I’m also unsure if I have a Friday exam this week that might become the main focus of my attention, completely putting me off my planned schedule of things to do for this week.

week 8 to do:

- This week I plan to spend time in the chemical engineering lab and design a test to see if our received pressure transductor properly measures the pressure within a system. I plan to design the test, so even if the pressure transductor hasn’t arrived yet I want to come up with a test for it when it arrives.

- I need to spend some time looking for a proper fitting for the pressure transductor to ensure it will fit into the bioreactor and my designed test.

- I also plan to go through the list of inactive users and delete them off the website.

week 7 update:

- these last few weeks I have been overwhelmed with exams and other school work to finish, after spring break I have more free time to dedicate to my project.

- I spent some time going over the list of active members and compared it to the list of users on the website. Now i need to go through and remove any inactive users on the website.

week 7 concerns:

- This week I have an exam on Monday and a big program worth as much as an exam also due Monday.

- the end of the week is spring break, I am leaving early in the week to go visit family. IM not sure I will be able to do much work this week as well.

Week 7 to do:

- design a pressure testing system for the pressure transductor.

- Email Cam about previous bread slice iterations and PCB files

- go through the list of active OSHE members and compare it to the members on the OSHE website.

Week 6 update:

- we had our CDR this week, it went well. I didn’t manage to get much work done as I had 6 exams over the last 7 days. With another exam Monday.

Week 5 concerns:

- Winter carnival is this week and I plan to spend the majority of the week not doing schoolwork, causing me to worry about the amount of work I will get done this week, when the CDR is next week.

- Still need to do my website dev work.

Week 5 to do:

- Finish CDR slides before week 6.

- email Daniel about the E-stop button and the previous slice KiCAD layouts.

- go through the list of active OSHE members and compare it to the members on the OSHE website.

week 4 update:

- The capstone members of our team got together and composed a list of parts we need to order over the weekend. Then on the following Monday we went into Shane’s lab and ordered the parts.

- We decided to use a car pressure transductor to monitor the pressure in the system.

- Spent time going over the bioreactor’s circuits learning how to build the slices better, also worked on the CDR slides as that is next week.

Week 4 concerns:

- Still need to go through the website, I got the list of active members from the secretary now I need to check it against the list of user profiles on the website. Look into making an assignment for the newer projects to make their profiles.

- Its hard to set up a meeting time with capstone students because everyone is so busy trying to graduate.

Week 4 to Do:

- We need to find a pressure gauge that meets all of our requirements, I will attempt to meet with the other capstone students this week to peruse and purchase a pressure gauge that best fits our needs.

- order the pressure gauge and start looking into electric parts for the bread slice

week 3 update:

- The team meet with Daniel from the chemical engineering department this week to go over how the bioreactor works. I now have a much better understanding of how the pressure control slice is supposed to work.

- We have determined that the $300 dollar electronic pressure switch is not the route the chemical engineering department wants to pursue, but rather a method to fully stop the system when the pressure in the filters reaches a set level.

Week 3 concerns:

- I potentially found a $300 solution to controlling the pressure within the bioreactor’s system using the psd-4 electronic pressure switch that the chemical engineering department might like more than using a bread slice to monitor and control the psi in the system.

- I have to go through the website and remove the old members who left the enterprise and I don’t know when I have time to do that.

Week 3 to Do:

- look into ways to measure and record the PSI inside the bioreactor system

- Do our weekly presentation on Thursday, seek support from the group for the pressure system.

- Meet with the chemical engineering department on Friday to test the bioreactor using water to gain a deeper understanding of how it works.

week 2 update:

- This week our team meet up with the chemical engineering department to get an overview of the bioreactor, and how it works. We meet with Daniel later in the week to go over the industry standard for the bioreactor control panel.

- we meet as a team on Monday to discuss how we should best move forward. We decided that trying to fit everyone’s schedule to meet with Dr. Techtmann wasn’t feasible for the amount of questions we want to ask so only one of the capstone members will be meeting with him to discuss the budget of the project.

BREAD BiOS Work Log

——————————————————————————————————————————————————————-

Week 6 concerns:

- I’m kind of worried that the team will get some heat for not doing enough by the CDR this semester.

Week 6 To Do:

- Continue working on the CDR slides

- keep looking into potential parts useful in the synth

- try getting the Arduino to read MIDI

Week 5 update:

- This week we had the career fair on Tuesday so our team couldn’t have our weekly Tuesday meeting, we all spent our own time working on the CDR slides then on Saturday a few of the members meet in the lab to go over the presentation.

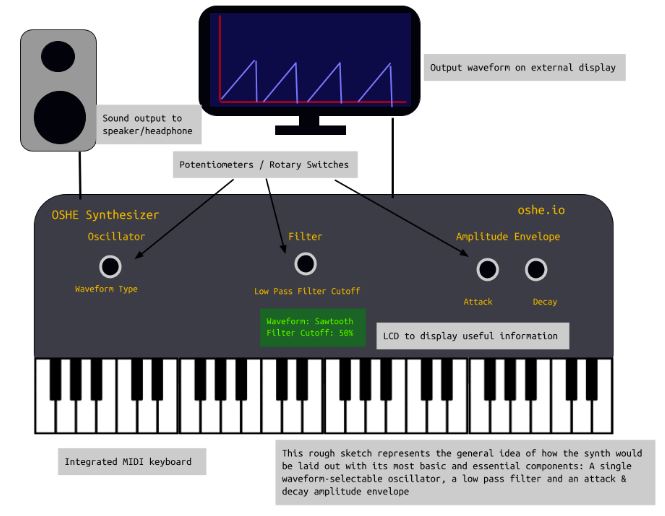

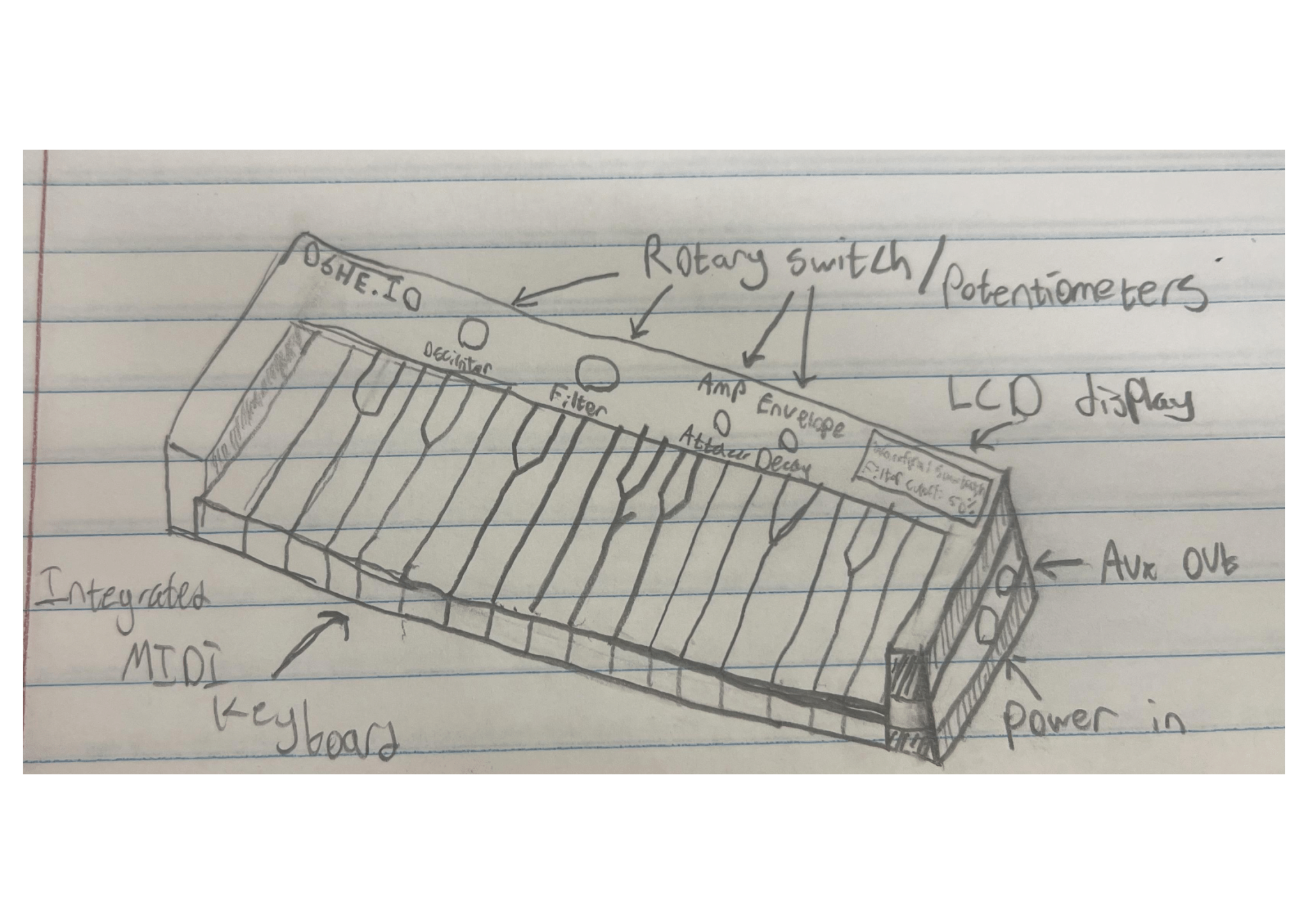

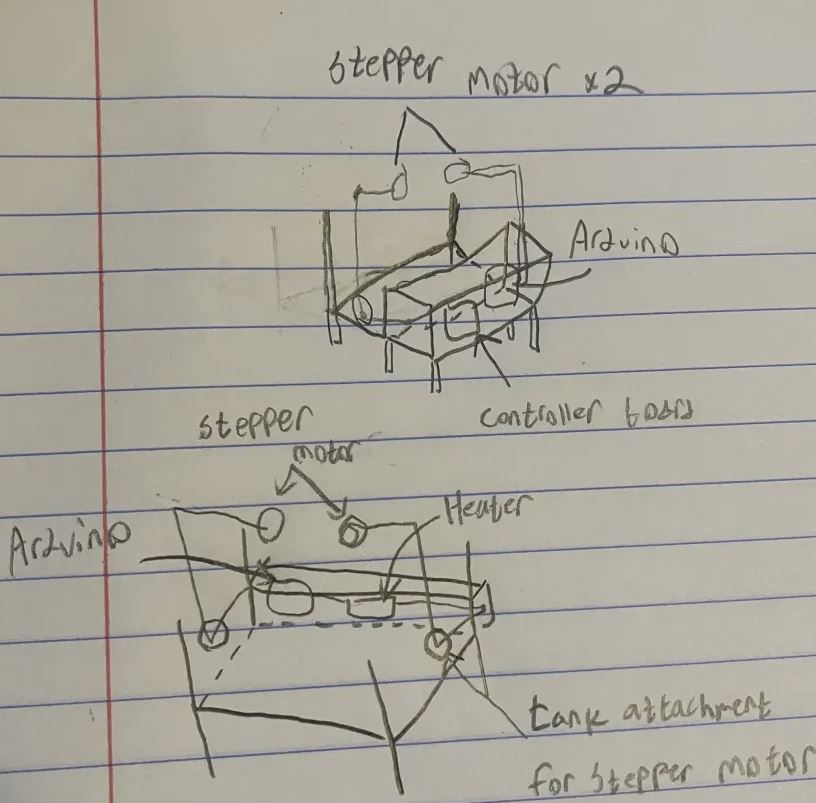

- The image below was designed by my teammates, it showcases our ideal final design for the synthesizer. There are four rotary switches responsible for controlling the synthesizer’s output, the function of each is labeled in the picture below. We also hope to include a built in LCD display to showcase output information to the user.

Week 5 Concerns

- I’m not sure when our group is supposed to present in class, and we don’t have a slides made yet. Ill try to figure out when our group presents this week.

- the CDR is coming up fast and we have to meet 20% of our project specifications.

Week 5 To Do:

- Continue working on the MIDI integration using the Arduino.

- make slides for the weekly presentations

Week 4 update:

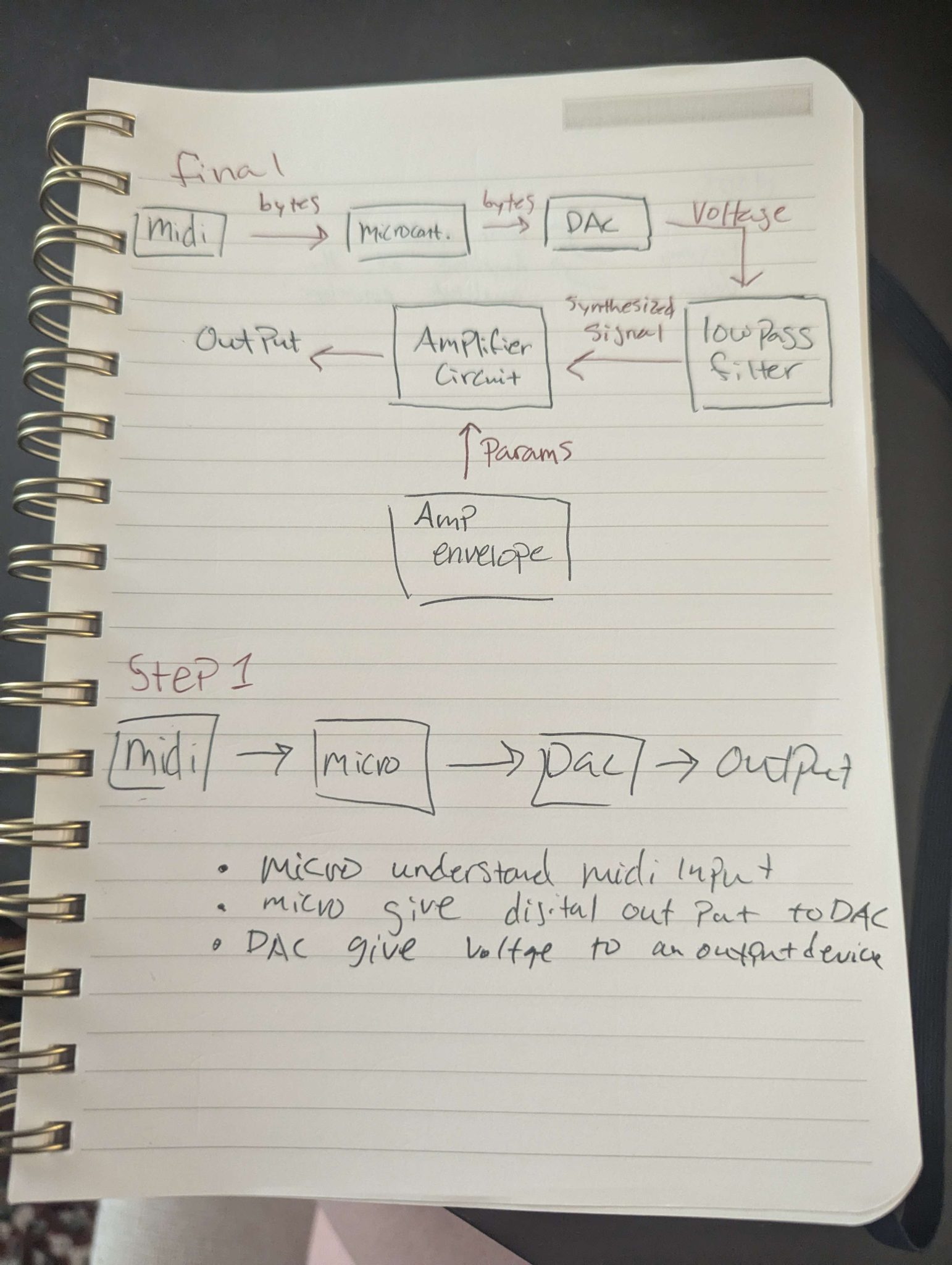

- this week we met up to work on generating output using Arduinos we found in the lab. We made a diagram showing off the general circuit design while meeting on Saturday, image shown below.

- we managed to generate a desirable triangle waveform output from the Arduino and measure it on an oscilloscope.

- During our weekly meeting I started on the slides for the upcoming CDR.

Week 4 Concerns

- I am not free at all this weekend to meetup with the team to help work on Saturday.

- we need to think about what we could present when our turn to present comes.

- Also need to start thinking about the CDR, need at least 20% of our design goals meet by then.

Week 4 To Do:

- Keep researching MIDI and how it works for the MIDI compatibility goal.

- keep searching for resources to help build the synth, parts, code, ect.

Week 3 Update:

- this week our team meet to revise our project spec, and decided to meet up Saturday in the OSHE room to start working on the first few logistical steps of building the synth. CDR is approaching fast

Synthesizer Work Log

——————————————————————————————————————————————————————-

Choco Fab Work log

Week 12 Update:

- This week Liam Kane and I managed to get the silicon molds made with the help of our friend Beau from Toys Tools and Technology. The molds are perfect, exactly what we wanted them too look like.

- Our group meet over the weekend to integrate the multiple separate parts we had been working on into a finished product. there were some minor issues with the housing not fitting correctly, however we managed to overcome said issues and managed to get the project put together for the most part. we will start testing this week.

Week 13 To Do:

- assembly the finished project and work on testing the functionality of the choco fab.

week 13 Concerns:

- We were having issues with our water pump not producing enough water pressure, barely generating enough to lift the water a few inches, when the box says the pump should be able to send water a few feet at a time.

Week 11 Update:

- I managed to print off a working electronics housing that fits all the required parts, and has the oshe logo on it! For now it works perfectly however the electronics haven’t been put inside connected up, so it might face more issues further down the line.

- our team meet this weekend to work on our report and discuss our plans for moving forward. Our final meeting with Shane was set to be Thursday the 25th and we still have to finish up a few major aspects of our project. If all goes well we should get a 90% or higher, if we run into too many complications we will have to meet again to discuss what we can feasibly finish before the 25th.

Week 12 To Do:

- We still need to finish our social media post, Liam Kane managed to get the 3D prints finished this week and is in contact with Beau, who is assisting our team with the silicon casting process. They will meet up Monday to cast the silicon and take videos for the OSHE social media.

- work with the team to update the project report, and integrate the many separate parts we’ve been working on into a finished project.

Week 12 Concerns:

- I am still unsure about the state of the electronic extrusion process, and am also growing more and more c concerned about the social media post that was meant to be due weeks ago.

Week 10 Update:

- I meet with Liam Kane on Sunday to construct the 3D prints for the silicon molds, we left them to print overnight and meet up with Beau, a friend of Liam’s who started his own company Toys Tools Technology LLC. Beau has experience with silicone mold casting so we sought out his help with our casting, and he recommended we do a test cast with the amazing re-melt material. This ended up helping and costing us greatly, the material ended up destroying our 3D prints however it revealed imperfections in the print that would’ve cost us down the road. Liam has been struggling to get the 3D prints to come out correctly since they were destroyed.

- I talked with Alex Olsen and he decided that we are using the Arduino Nano for our final circuit so I took the mega out of the electronics housing design and am currently 3D printing in the OSHE room. The print is expected to take around 8 hours which means it will finish late into the night, as such I will leave after the first few layers are printed and return when it finishes.

- I also attended the 3D printing seminar in the OSHE room on Thursday and learned the basics of printing by printing a benchie of my own! It is super simple for the most part however my laptop only holds a mini SD card, and the 3D printers only take SDXC cards. Luckily the lab has microSD to SDXC adapters so it wasn’t a problem.

Week 11 to Do:

- I need to make sure the 3D print works with the electronics, if the wire holes or the indent for the water temperature controller is off I will need to re-print the housing. This also falls under my week 11 concerns but I will not list it twice.

- We still need to finish our social media post. Liam Kane is on the social media team and was on point for the social media post for the choco fab team, whoever because the silicon molds aren’t cast yet, which is what we were planning to showcase in the social media post, Liam gave the choco fab team an extension on the assignment as the enterprise social media expert.

Week 11 Concerns:

- I am unsure if we will be able to complete the electronic extrusion for the choco fab by the required deadlines. Our team is meeting this weekend to discuss our steps going forward.

Week 9 Update

- This week I had to alter the electronics housing design again based off the time it would take for the print. I have to make it small enough to be able to print in under 12 hours and we plan to accomplish this by refining the electronics to have less components.

- me and Liam Kane are meeting Sunday to make food safe silicone molds.

Week 10 to Do:

- Get in touch with Alex Olsen about the finished circuit to figure out which components need to be kept in the electronics housing.

- Work with Liam to print the silicone molds

- attend the 3D printing seminar in the OSHE room this Thursday to learn how to print using the 3D printers in the Oshe room.

Week 10 Concerns:

- I am unsure when Alex Olsen will get in contact about the updated electronics.

- I need to develop the featured webpage for the OSHE website.

Week 8 Update

- We were going to 3D print on Thursday however I had to re-fit electronics housing model for the 3D printer in the OSHE room again, this time it’s 10 inches, give or take a half and inch, and should fit inside the printing area with no issue.

- there were time conflict issues with Liam Kane and his silicone contact this week and we couldn’t figure out a time to get together to talk about the silicone molds.

- I updated the Bill of materials with the food grade silicone tubes we ordered.

Week 7 Update

- This week was rough for me, I had a bunch of quizzes and an exam to work through, so my plans to start 3D printing this week didn’t go through

- This week as a group we worked on updating our OSHE project page using the new format.

- I discussed the Silicone mold options with Liam Kane, we discussed weather to make customized silicone molds that may fit our specific needs better than a store bought mold as the store bought molds aren’t the correct shape and size for our chocolate extrusion system.

Week 8 to Do:

- I still need to 3D print the electronics housing

- work with Liam towards the customized silicone molds

- Work on a new featured section for the OSHE website for the OSHE enterprise responsibilities.

week 8 concerns

- I am unsure of the current state of the 3D printers in the OSHE room, I know there have been various problems with them printing incorrectly in the past

- Liam is still unsure about when we can actually start making the silicone molds

Week 6 Update:

This week our group meet to discus our plans for the upcoming half semester, I updated the electronics housing design to hold the arduino board and its attachment better

week 6 to Do:

print the electronics housing design

look into getting silicon molds made with Liam Kane.

Week 5 Update:

- This week our group had our Central Design review with the rest of the class, We got a lot of great feedback from the class which we will be using to help move forward in the project

- I didn’t do much work this week because I was distracted with 3 Exams and a quiz, and a Lab.

Week 6 To DO:

- SPRING BREAK!!

Week 4 Update:

- This week I meet with members in my group to discuss our options for food grade silicone molds

- I found some measurements online to begin making the Electronics housing in free CAD

Week 5 To Do:

- Finish making the electronics housing and get input from team members

- prepare the CDR slides for our review this week

- get the measurements for the rest of the components for the electronics housing

Week 5 Concerns:

- As it turns out our part order didn’t go through so we had to re-order our parts this week, and re-think what is possible for our team by the middle of the semester.

- I need to figure out what specific new parts from around the lab that were added to the project in place of the parts we tried to order to add to the BOM

Week 3 Update:

- This week I made our bill of materials

- We meet as a group to make a Gantt chart for this semester

Week 4 To Do:

- Measure the size of the parts that go in the electronics housing

- Design the electronics housing frame in an open source CAD software

Week 4 concerns:

- Unsurprisingly the parts still haven’t shown up yet, so our group is having problems moving forward in out project.

Week 2 Update:

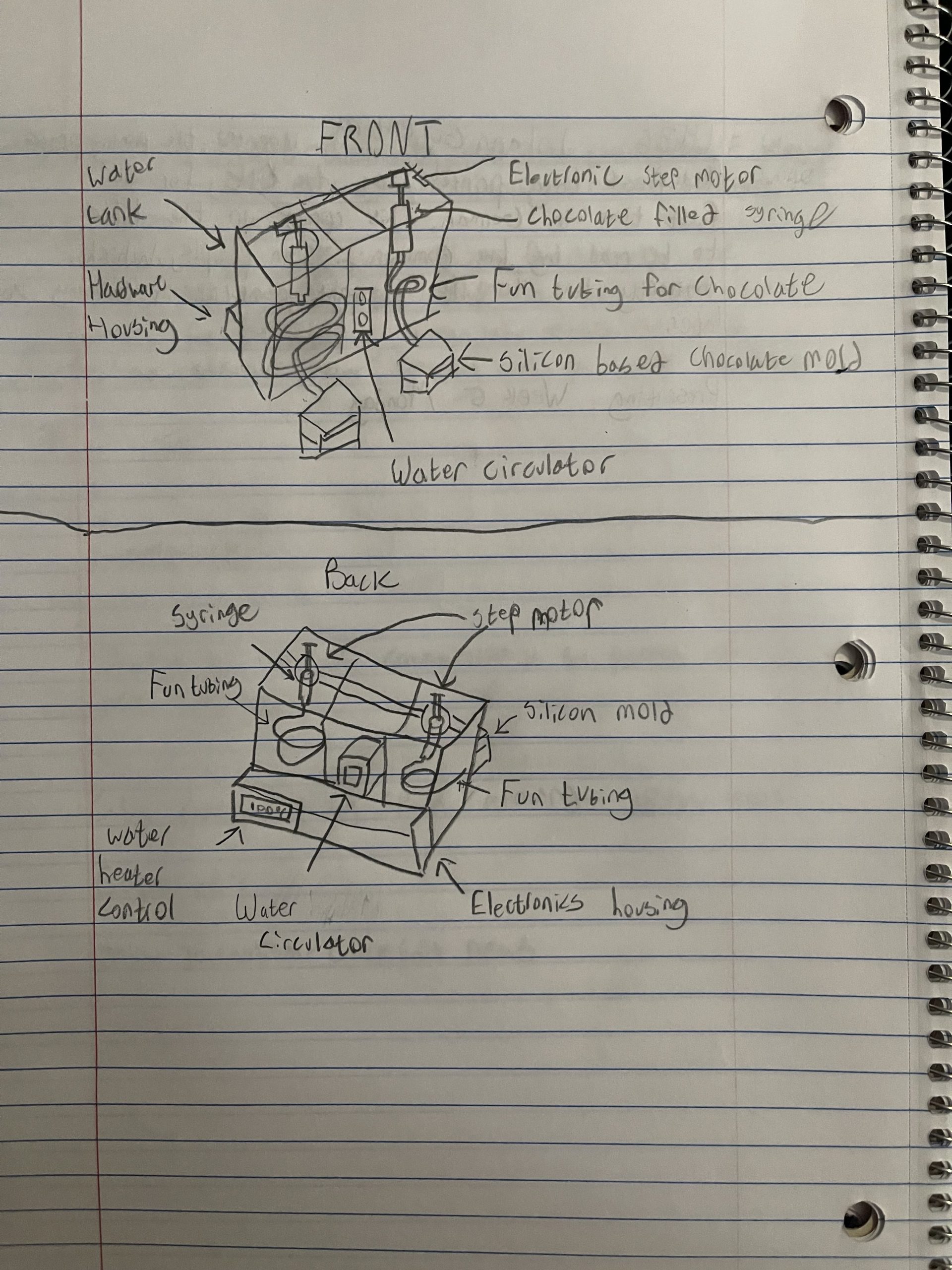

- This week I made a sketch of what we want the electronics housing to look like, but without the size of the components I didn’t make anything in CAD

- Our group meet to discuss what we did, and what we have to do next week

Week 3 To Do:

- Measure the size of the parts that go in the electronics housing

- Design the electronics housing frame in an open source CAD software

- get old parts and materials list to update with new parts

Week 3 concerns:

- The parts haven’t arrived yet so I have the same problem as last week, I cant view the parts to make a better electronics housing design

Week 1 Update:

- This week I received the items, price, and URL for the project’s parts and materials list

- created my website Profile

Week 2 To Do:

- work with group on new parts and materials list

- Design the electronics housing frame using open source CAD

week 2 concerns:

- for the Electrical housing I need to measure the components to make sure they all fit nicely, but a few electrical components that we ordered haven’t shown up yet so I’m not sure of their exact size