BREAD Standards Update

9/29/24

Progress

- Got CAN communication working on breadboard

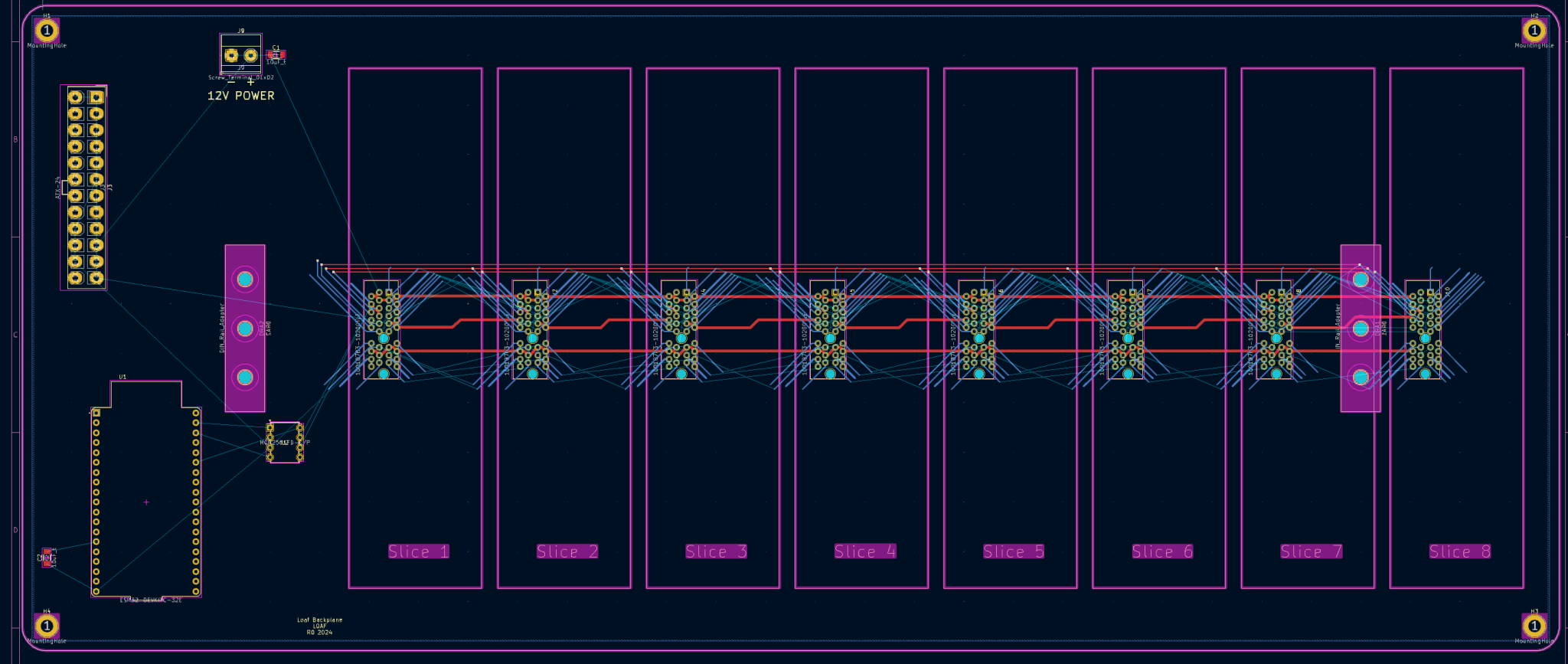

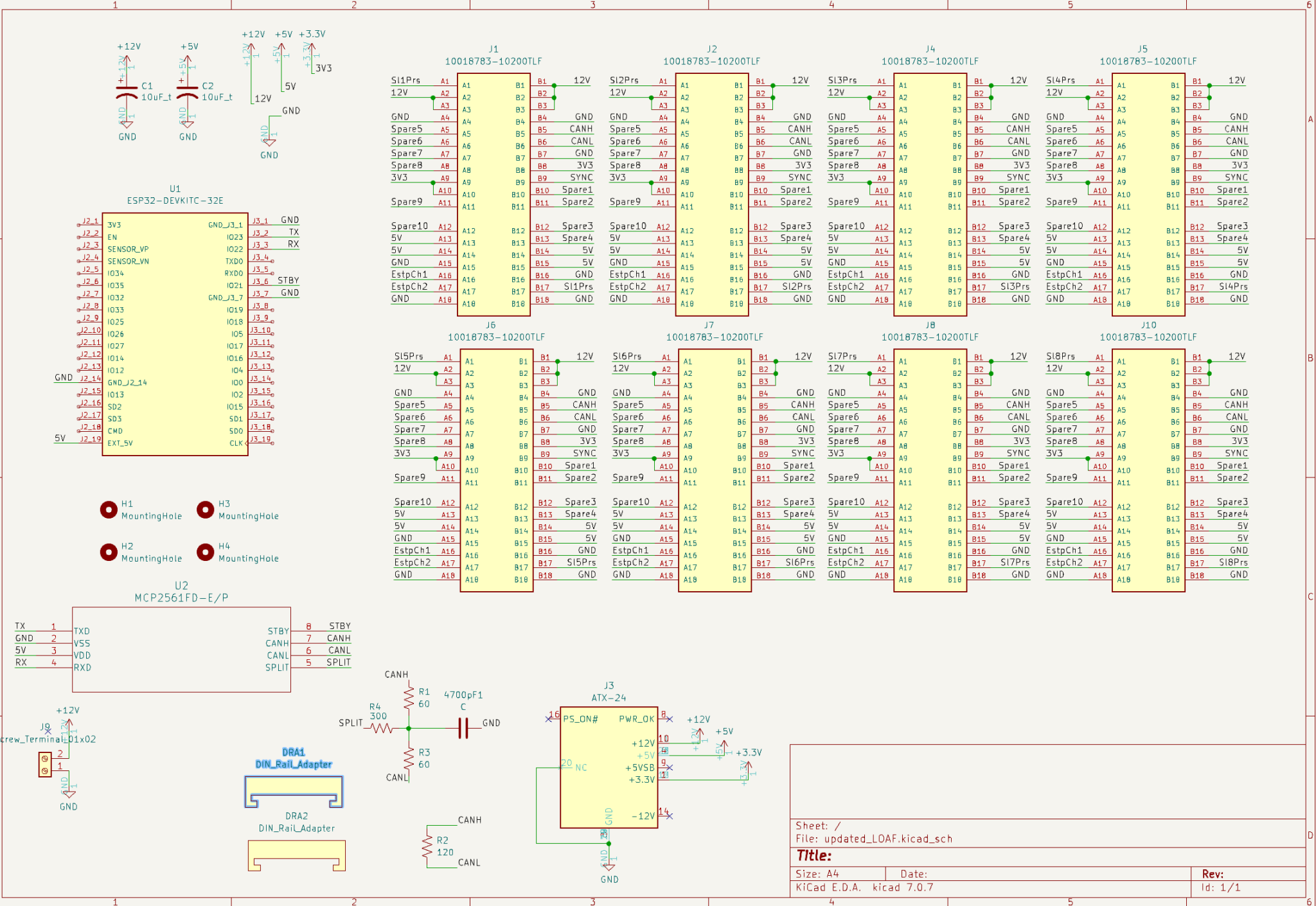

- Completed Loaf schematic and worked on PCB layout

- CDR prep

To Do

- Complete and Order Loaf PCB

- Review DAQs updated PCB

9/20/24

Progress

- Received parts

- CAN transmitter and receiver breadboarded

- Started Loaf schematic and PCB updates

- Met with UWO to discuss their work on BREAD

To-Do

- Complete and review LOAF design

- Test CAN breadboard setup and verify functionality

9/13/24

Progress

- Ordered components

- Project planning

To Do

- Complete updated LOAF schematic draft

- Spec edge connectors and determine price different

- Spec ATX connectors for powers standard

- Begin breadbording

- Regroup with recyclebot

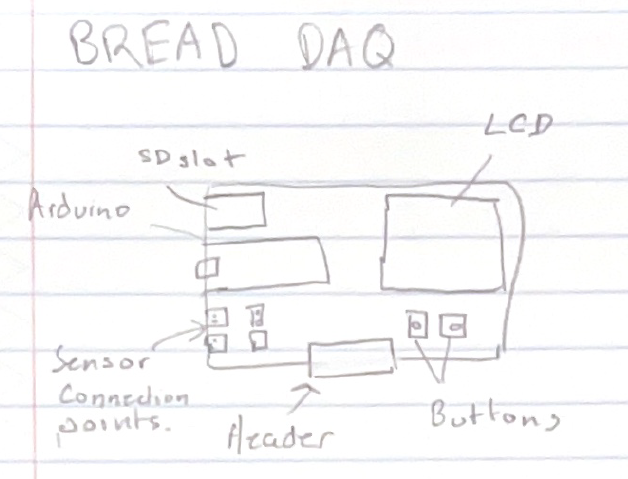

BREAD DAQ

4/20/24

Progress

- Worked on Report

- Uploaded files to OSF

To Do

- Complete final touches on Report

- Complete checkoff

4/12/24

Progress

- Translation code finished and verified

- Report draft complete

- Resistive sensor tested

To Do

- Complete report

- Clean up documentation

- Prep for checkoff

4/6/24

Progress

- Code combined and debugging began

- Translation code 75% complete

- Set up and configured SQL server

To Do

- Finish debugging Arduino code and test

- Complete and test translation code

- Clean up BOM and other documentation

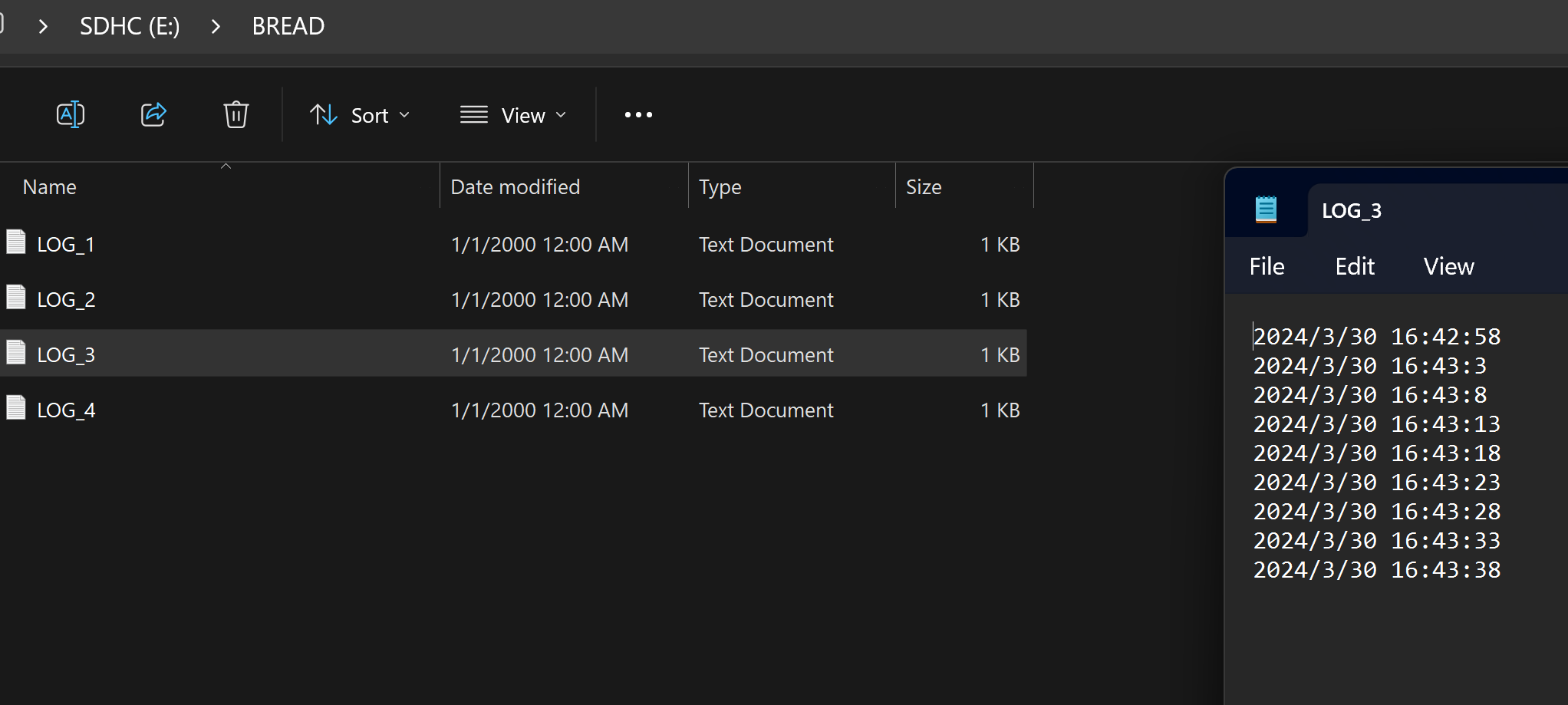

3/30/24

Progress

- Got external RTC working

- Worked on Integrated RTC (Not able to get time working)

- RTC logging to SD card

To Do

- Work on transition code

- Continue work on integrated RTC

- Combine codes to make main slice code

- Work on LOAF communication.

3/24/24

Progress

- Completed Soldering board.

- Tested SD code

- Made Updates to PCB to fix issues

- Began Work on RTC

To Do

- Troubleshoot and program RTC

- Potentially order updated PCB

- Work on combining codes

- Work on SQL and translation code

3/16/24

Progress

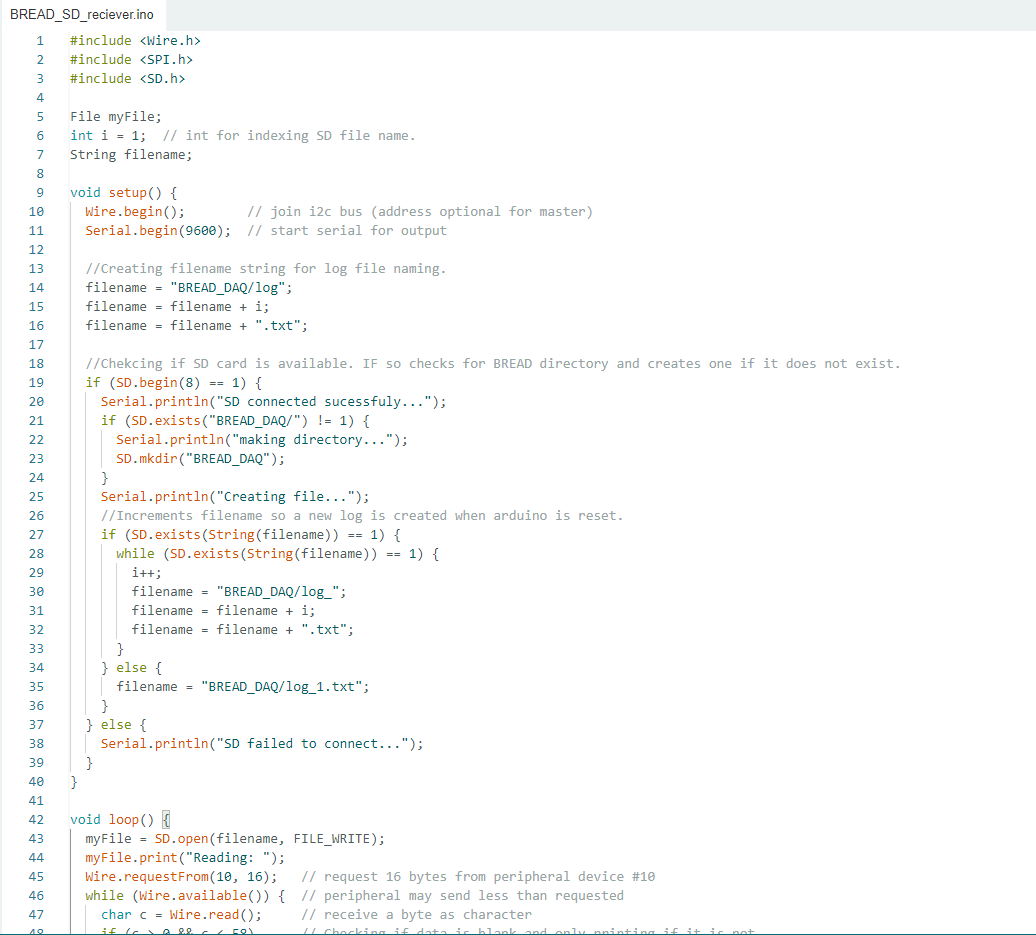

- Began work on SD code

- Received PCB

To-Do

- Solder PCB

- Continue work on SD code

- Set up SQL server and begin translation code

3/9/24

Progress

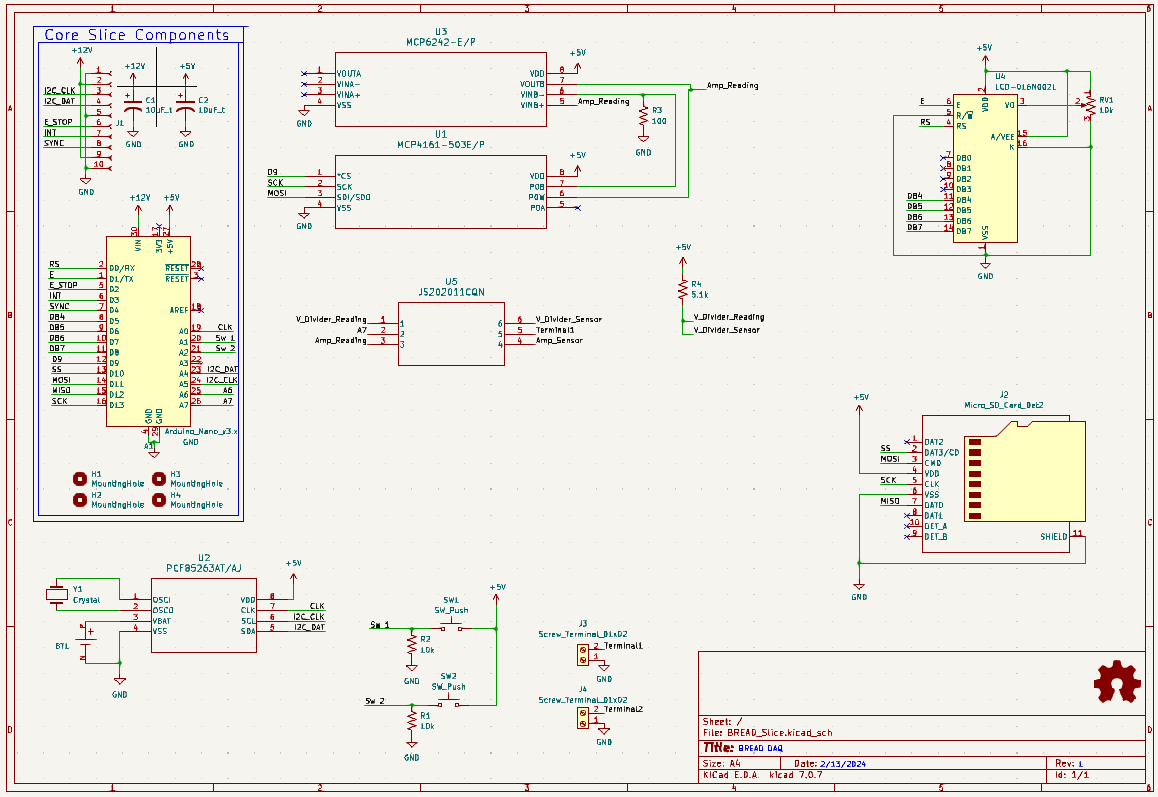

- Completed PCB Design

- Ordered PCB and components

- Replaced Amplification circuit with ADC to read thermocouple

To-Do

- Work on SD logging code

- Solder PCB and test once parts arrive

- Set up SQL server to write logged data to

2/24/24

Progress

Recap

- Added improvements to PCB design

- Worked on Amplification circuit

- Added switches so that terminals can be used for both Amplification and Voltage divider circuits.

To Do

- Complete Amplification circuit

- Finalize and order PCB

2/17/24

Recap

- Completed CDR slides

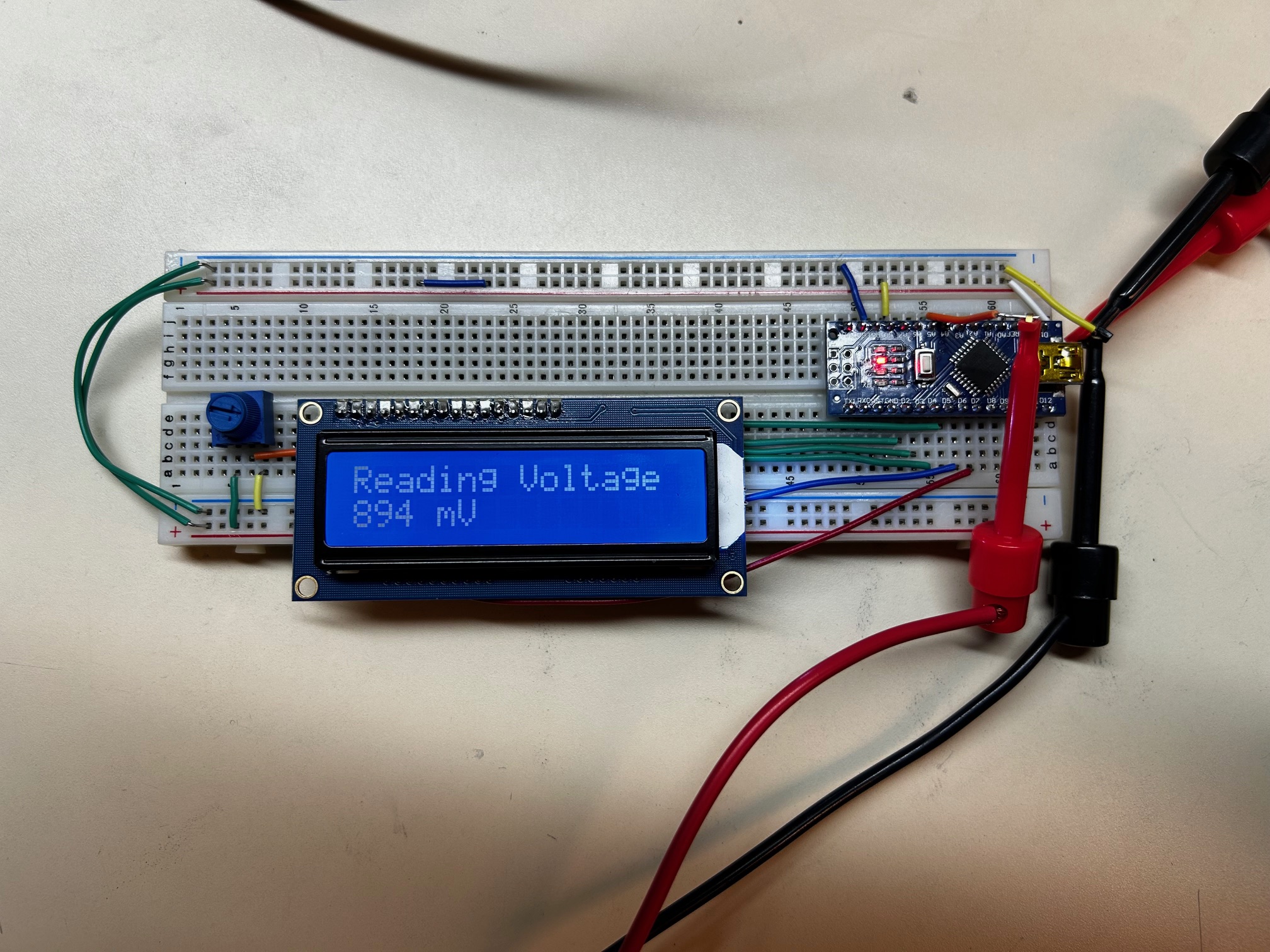

- Breadboarded the Op-amp and potentiometer circuit and began testing

- PCB design draft completed

- Made Voltage reading display and conversion on LCD

To Do

- Review and order PCB

- Continue work on Amplification circuit.

- Work on buttons to cycle sensor type.

2/10/24

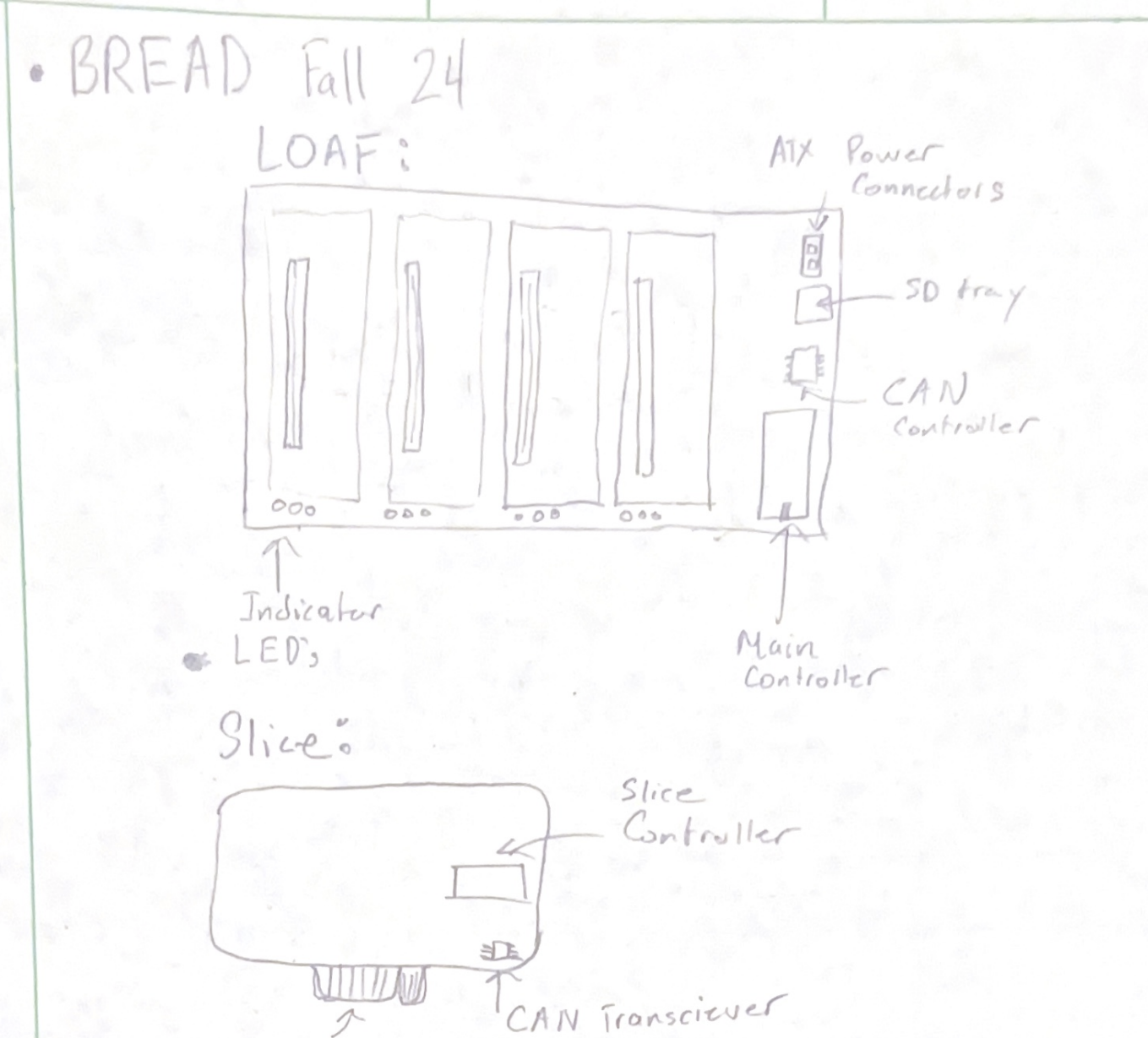

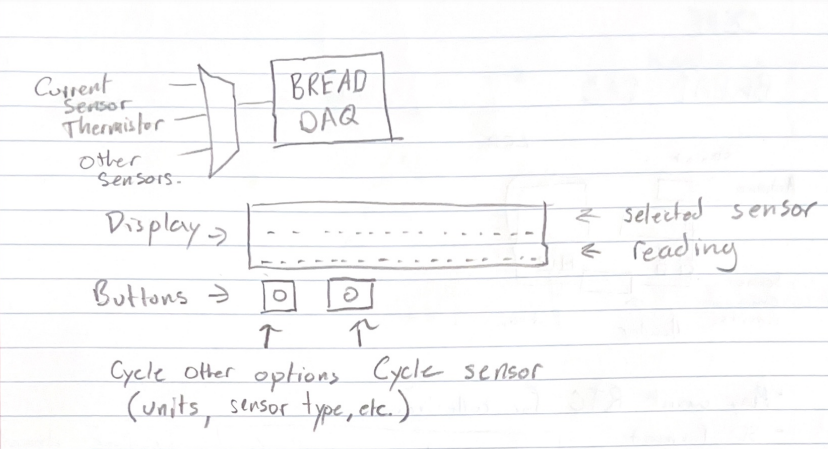

Sketch

Recap

- Completed schematic design for RTC, LCD, battery backup, and Arduino.

- Completed skeleton code for LCD.

To Do

- Complete Op amp and digital potentiometer schematic design.

- Begin PCB design.

- Breadboard and test design.

2/3/24

Recap

- Began breadboarding.

- Ordered Parts.

- Began breadboarding and programming for LCD display.

- Skeleton code made for unit/sensor conversion

To Do

- Begin breadboarding measurement circuit once parts arrive.

- Connect to digital potentiometer to set resistance.

- Develop Amplifier circuit for measurement.

- Begin PCB design.

1/27/24

Sketch

To Do

- Begin Breadboarding.

- Work on LCD code.

- Research and begin code for data conversion.

- Develope circuit for sensor amplifier.

BREAD Vision

11/4/23

Recap

- Completed final design Changes to PCB.

- Re trained Yolo model to improve defect detection.

- Printed a new camera mount.

To Do

- Work on I2C communication.

- Order PCB.

10/28/23

Recap

- YOLO running and detecting objects on Pi

- Modified and improved slice PCB design

- Fixed Wifi connectivity issues with Pi

- USB camera code is functional

To Do

- Order PCB

- Improve image recognition consistency

- Implement I2C communication to Arduino from Pi

10/7/23

Recap

- Completed Slice Schematic and Board layout.

- Printed mount for spectroscopy camera.

- Captured and boxed images of a sample cup to train our YOLO model.

To Do

- Review and order PCB for physical slice.

- Continue working and refining YOLO model.

9/22/23

Recap

- Downloaded and installed all necessary programs to work on the Raspberry PI and Arduino.

- Received our USB camera.

- Set up TeamViewer on the Pi so that remote work and file transfers can be done remotely.

- Began work on physical slice.

- Went thought the documentation and guides for YOLO algorithm.

To Do

- Complete rough schematic of slice to be reviewed by team.

- Begin plan for collecting and training algorithm.