Multifx (digital petalboard)

Project Overview:

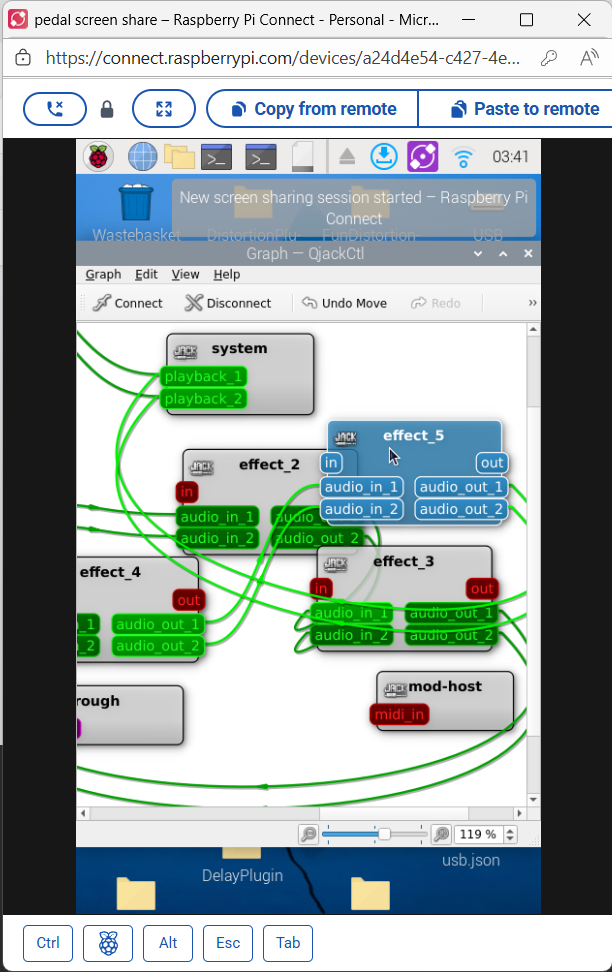

The MultiFX project is a modular, open-source digital effects processor built around the Raspberry Pi platform. It’s designed to emulate the functionality of professional-grade guitar pedalboards by chaining LV2 audio plug-ins through JACK and controlling them via a custom PyQt5 GUI and MIDI footswitch hardware.

My contributions focus on integrating the software and hardware layers into a cohesive, reproducible system from remote deployment through Pi Connect, to the audio service chain debugging that keeps JACK and mod-host stable, to the mechanical design that makes the hardware rugged and stage-ready.

Contributions:

- Developed and tested Pi Connect, a remote Raspberry Pi linking system that massively streamlined deployment and management across multiple devices in the project cluster.

- Worked extensively on Issue #14, investigating complex configuration and service-dependency problems between JACK, mod-host, and the GUI. While the final solution drew from legacy code by a former dev, I mapped out the breaking points and system dependencies in depth. This groundwork that clarified how everything fits together now that the system runs cleanly.

- Assisted with debugging of startup scripts, testing various JACK service timings and environment configurations for more reliable audio initialization

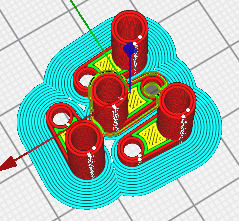

- Designed and 3D-printed a custom LCD stand-off bracket, improving durability and cable routing for the main pedalboard display.

week 2 update

Creating my To Do list:

- organize my goals

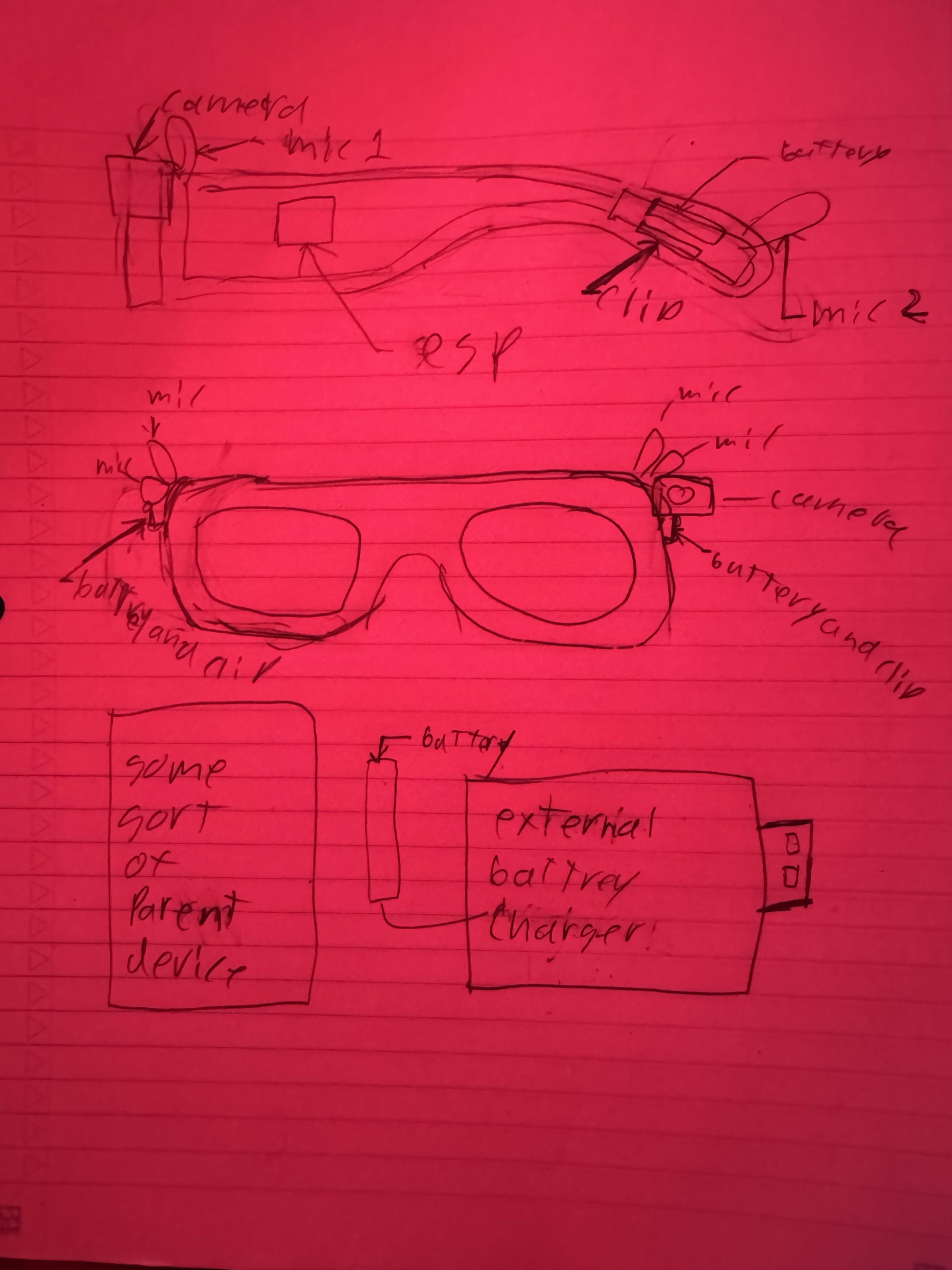

- Simple single cell BMS

- Under & Over current protection

- Fault protection

- Step-up

- Battery level monitoring

- Thermistor

- PMIC

- Unpluggable battery

- One on each esp

- Might need another for the camera

- Mini drone batteries

- Run time calculations

- Clip on, using parametrically modeled spline to facilitate batteries of different sizes.

- Off board charging (do we really want to charge the batteries with the glasses or have a standalone charger

- I think I’m going to do more research on existing BMS

- I have some Onshape project the I have made in the past that I think will work well for holding the battery, they can be quickly replicated this week

- a major thing I need to do with my team is figure out spacing for parts of the project

- I need to set up a development environment for prototyping the code and hardware for the BMS

- dedicated file system

- insure access to repositorys

- learn lab resources

- I have a bread board to use

- pick up esp from team

- I need to take the boards to the lab and get an idea of the power draw.

my only concern is not really a concern, but I’m sad because I don’t think we will have a near eye display.

week 1 update

I was mostly learning about how the enterprise operates. I meet my enterprise team and got caught up in the project.