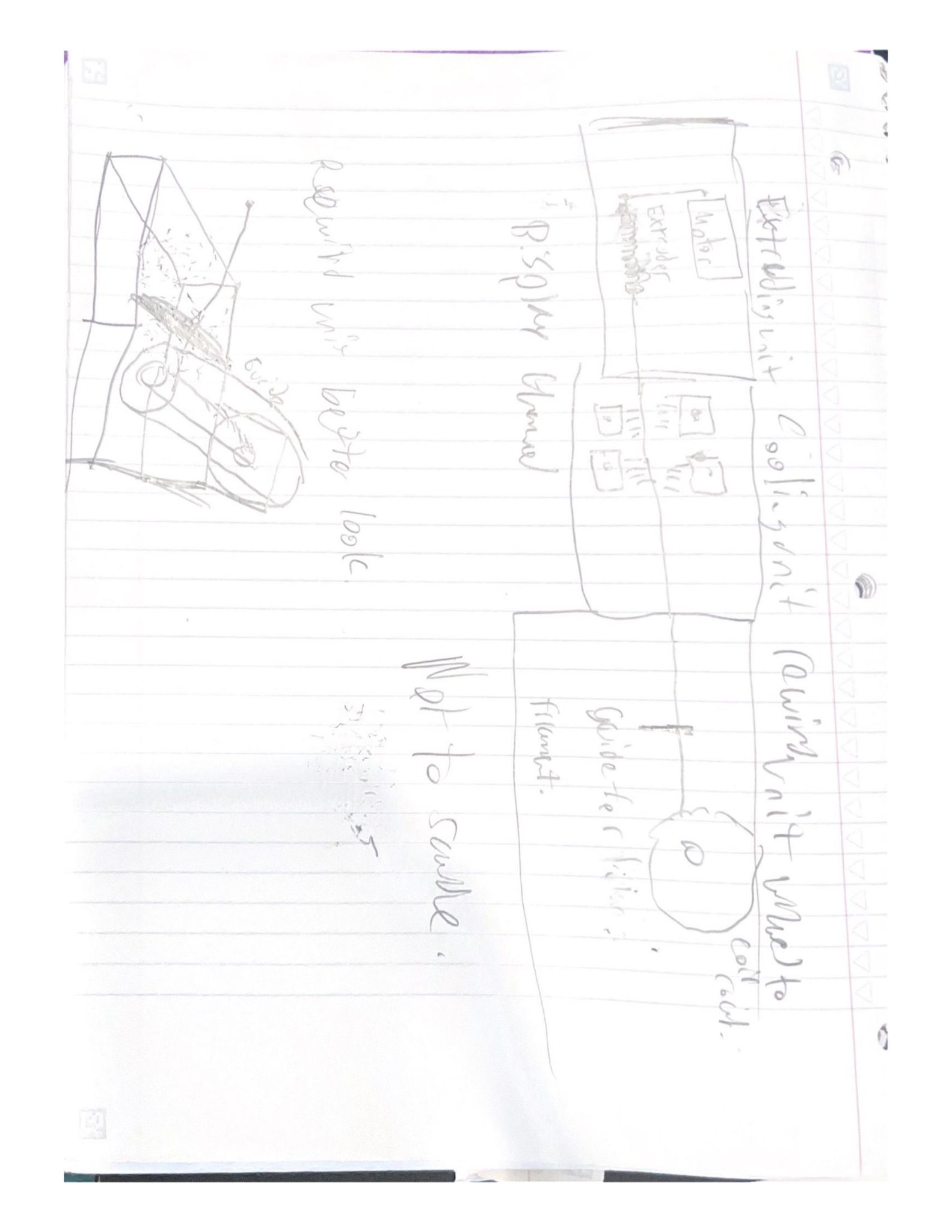

To Do :

Discuss with BREAD the type of board we’ll be using for the project.

Determine the type of guide we should use for the filament in the rewind unit.

Explore options for holding the roll while the filament is being coiled.

Decide on the motors we’ll need for the filament rewind process.

Figure out how we can ensure that the filament well go into the filament guide.

Concerns :

n/a

Log 2 :

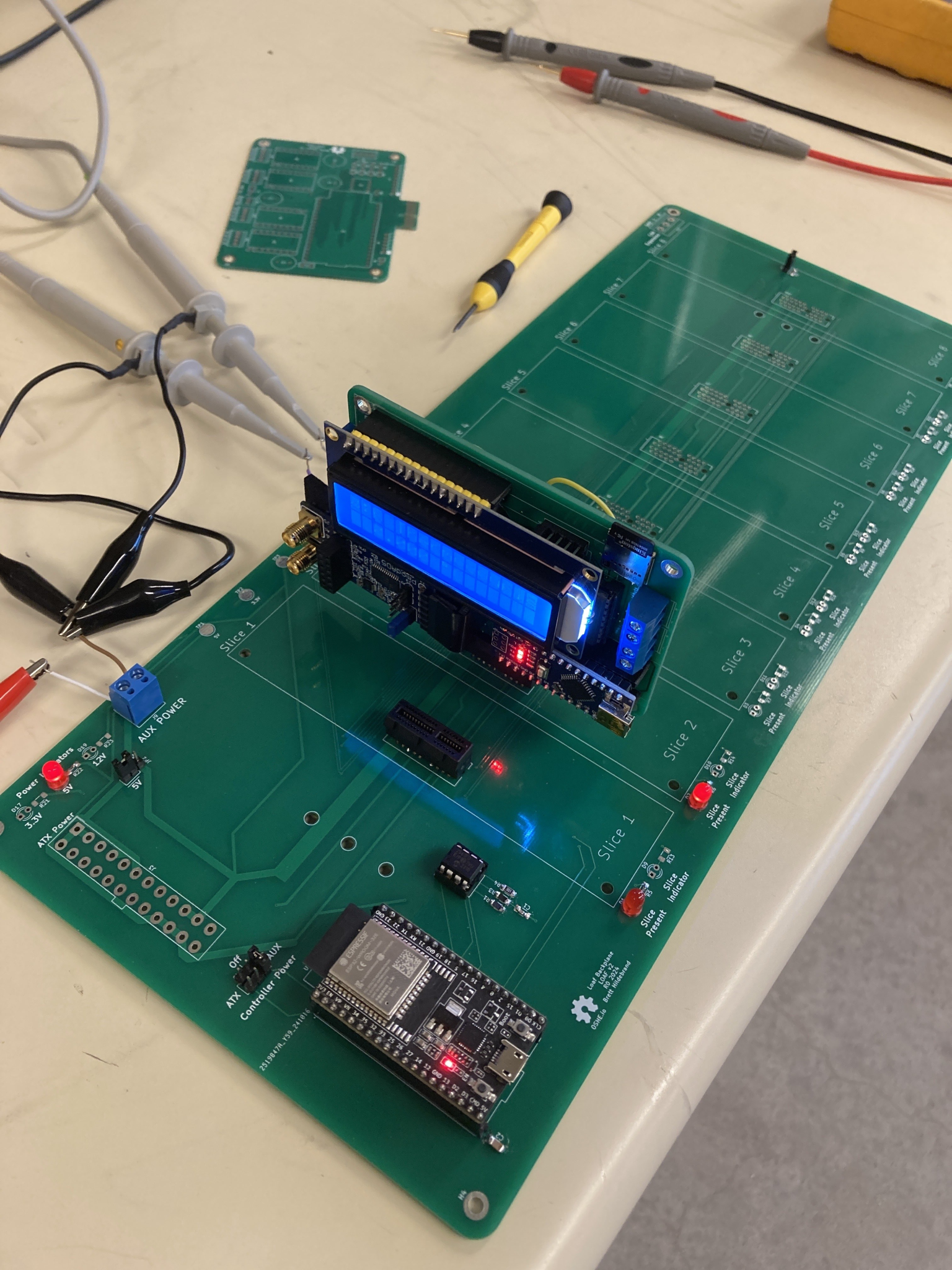

I was able to discuss with Bread about the board we would be using for the rewind unit. We also explored options to hold the filament in place. I also added some research into this for the filament measurement portion.

We did some collaboration on the motors to prototype with. I didn’t finish finding a guide.

To Do :

Determine the type of guide we should use for the filament in the rewind unit.

Determine a camera and mirrors used for measuring filament

Determine a better option for a spool holder

Make a shell around the camera to hold it in place for measuring the filament diameter.

Log 3 :

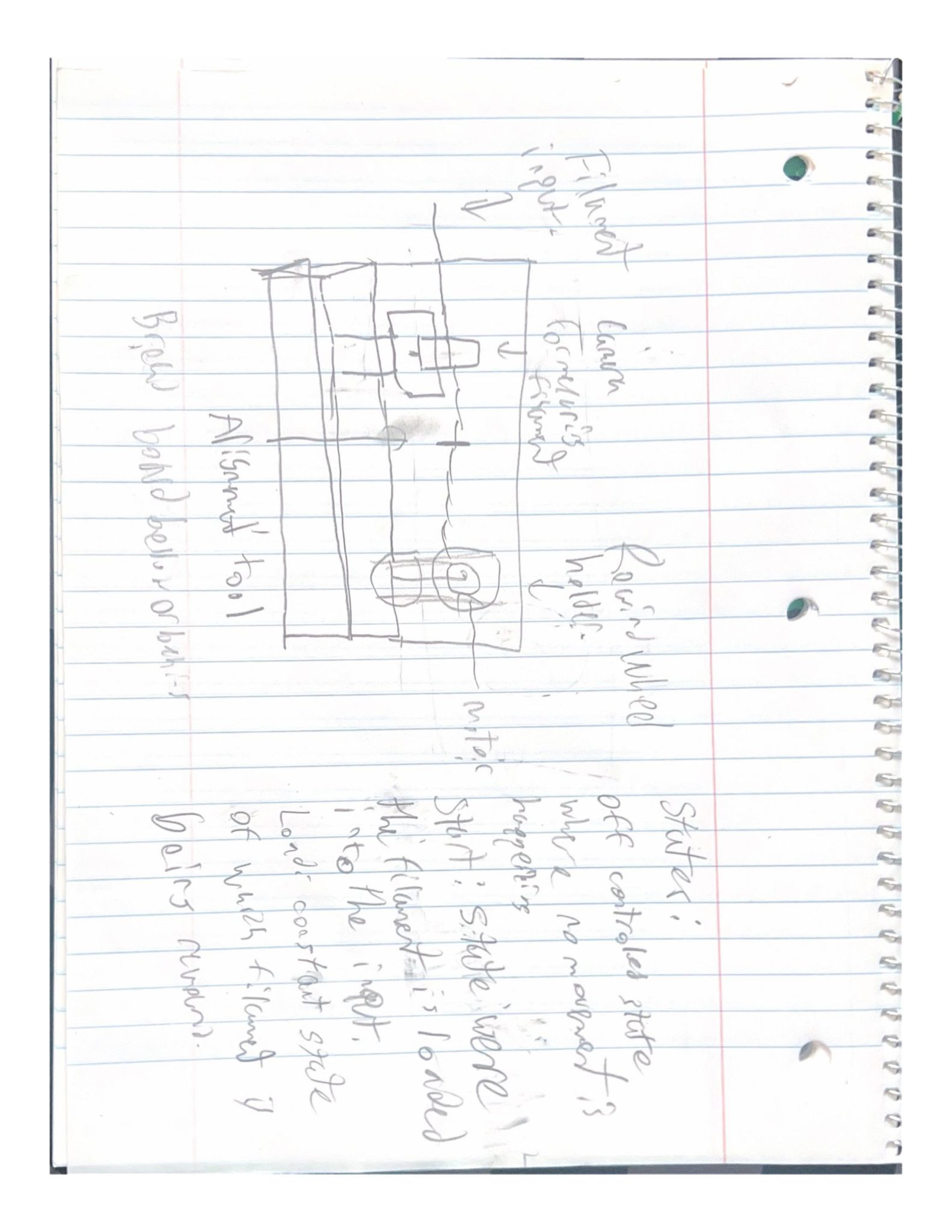

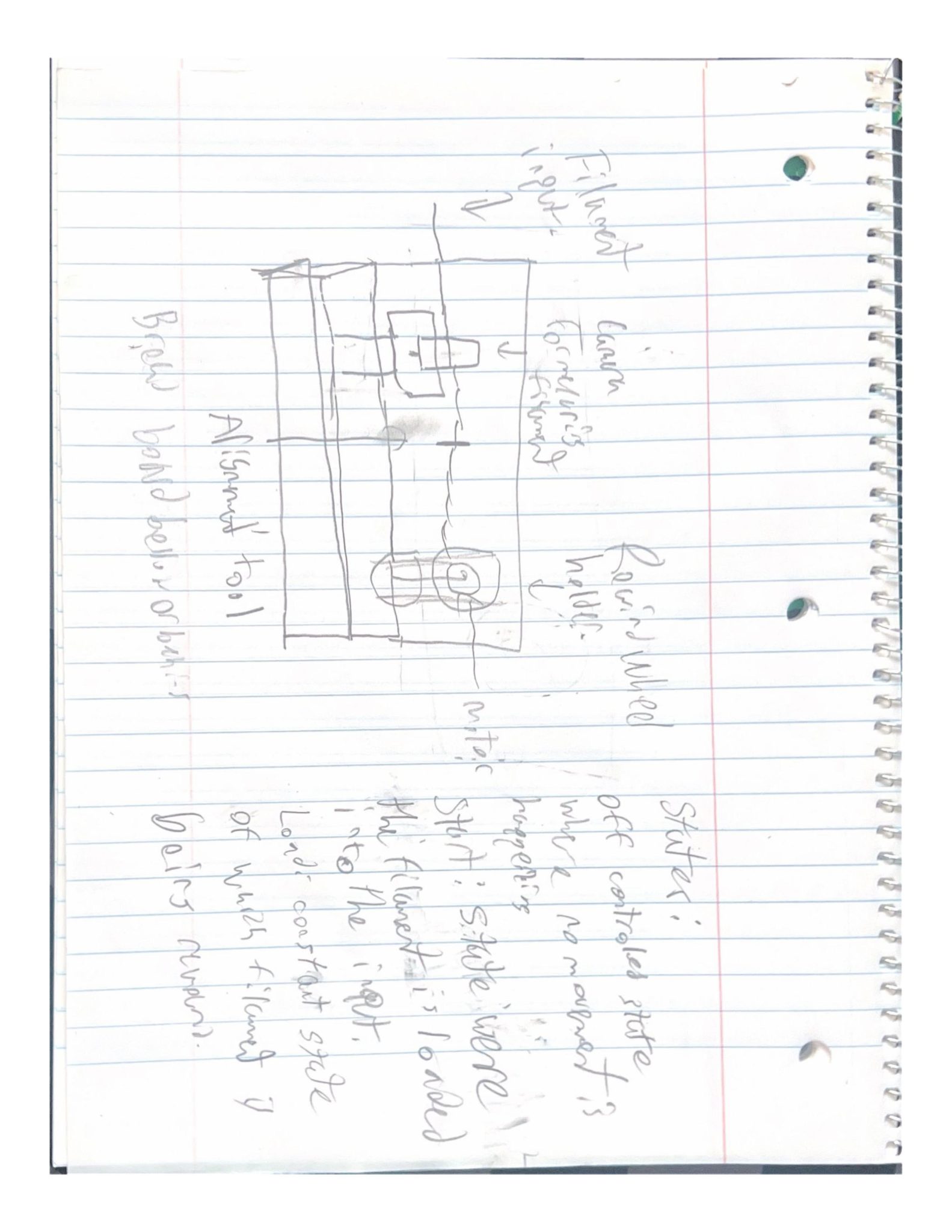

States :

Off : completely no motion in the machine, normally no filament in also.

Start : Status where filament is just loading into the rewind unit

Load : constant movement based off desired speed, length, etc.

Last week acomplished :

Found a camera and mirrors

Did some research on spool holder

Found a shell for a camera that we could

Did research on a guide idea

Next week to Acomplish :

Talk with team about the camera and mirror

Talk with team about the spool holder

Talk with team about the spool holder

Prepare for CDR and Enterprise Day

Concerns :

Finding time between 4 exams, CDR, and Enterprise day

1/23/25

To Do :

Finish 3d printing winding stand, filament guide, and gauge sensor mount

Create a new gauge sensor mount for the current rewind stand

Work on printing the new filament storage solution.

Prepare for BREAD boards to arrive.

Meet with Nasi to discuss filament solution (I’m sorry for missing you on this lab task)

Concerns :

n/a

Project Update 2 (1/26/2025)

What I did :

Lab task :

Meet with Noah, Eric, and Nasi to discuss filament storage solution and implementation

Print out a prototype of the shelf.

Find out things we should improve (exz clip for labeling the filament)

Implement the first iteration of the filament storage shelf without the clip into the lab.

Recycle-Bot :

redesign the filament gauge sensor.

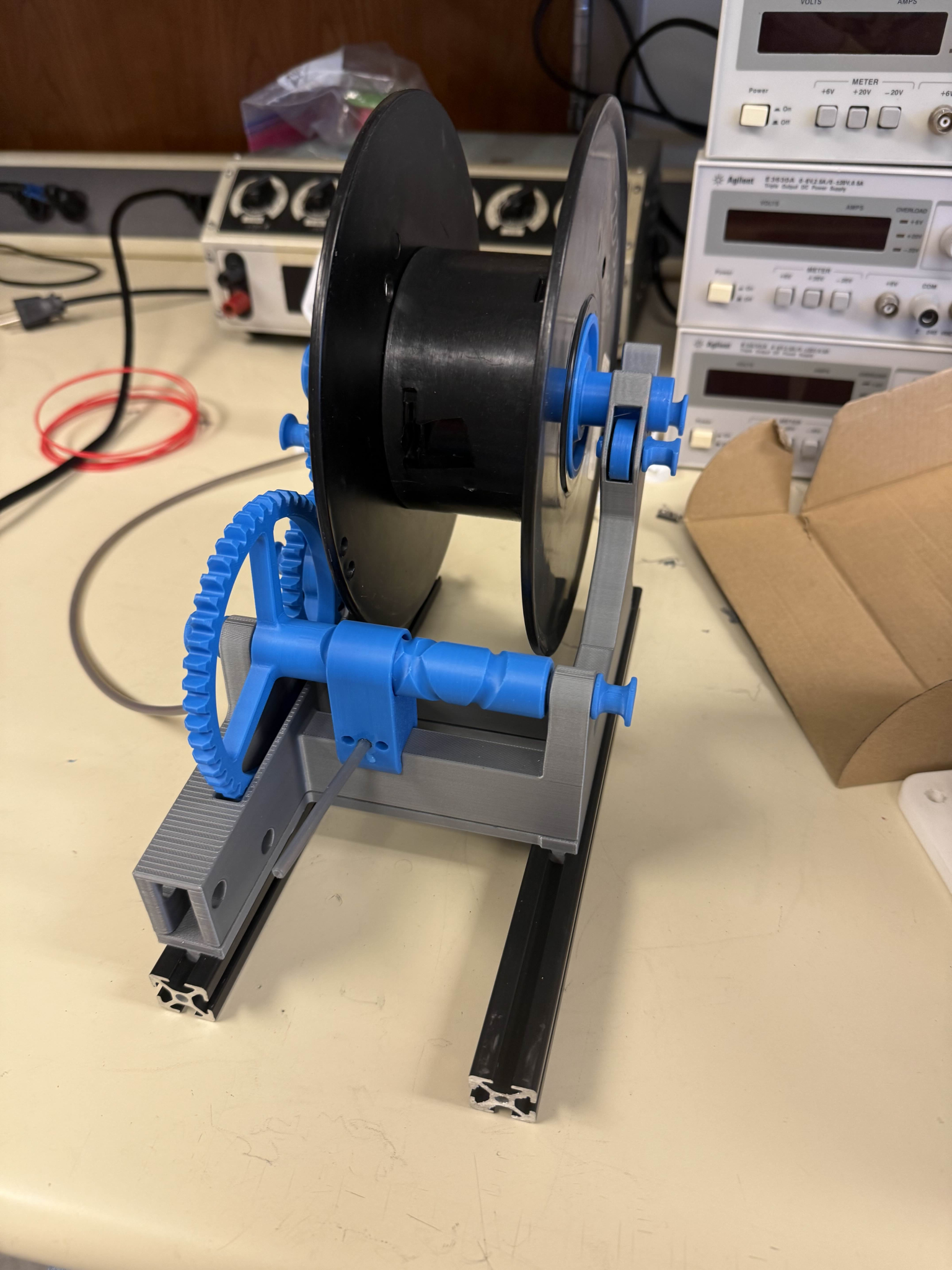

Found a new design for re spooling that would work slightly better

design a mounting bracket for this new design (see pictures bellow) to a 20×20 mm aluminum extrusion.

Test the bracket strength to see how much this would vibrate under low, medium and high speeds. Even though we’d primarily be testing this under low speeds and maybe medium speeds (using a drill and a 4 mm drill bit).

To Do :

make a motor mount / adapt a motor mount for the system.

Create a 5 mm drive shaft to a 4mm hex key adapter.

Further implementation of the same shaft as beforehand.

Concerns :

Timing, busy week (exam and a program) on top of normal workload.

States :

Off : completely no motion in the machine, normally no filament in also.

Start : Status where filament is just loading into the rewind unit

Got to design a new motor mount stand and start planning on rebuilt frame.

Tested a motor mount

To Do :

Create a 5 mm drive shaft to a 4mm hex key adapter.

Proceed with BREAD integration,

2/16/25

Finalized the design of the mechanical rewind.

Start trranslating software over to bread logic and be more responsive based off infidel

To Do:

continue translating bread logic

work on preparing the machine to produce a roll off filament with Konnor.

3/1/25

I was able to starting translating the software, did not finish translating it across two esp for bread logic and data logging.

To Do:

continue translating bread logic

work on preparing the machine to produce a roll off filament with Konnor.

Concerns

Bread Board delayed shipping.

3/9/25

To Do:

continue translating Language

Finish bread hardware.

Concerns

Timing with exams and progarams

3/16/25

code should be updated to current fourm

Todo:

switch language translated to vscode instead of audrino IDE (shouldn’t take long)

Continue working on hardware.

Concerns :

n/a

3/23

We created a roll of fillament not at diamiter speck. We did not have the infidel wired up because we have to rewrite the bread can protical for our project.

The controll loop should be done we just do not have infidel to check this at the current moment.

ToDO: tune infidel to the new rate.

Set up transmition with can.

Concerns :

timing : with CDR next week, we want to have a full roll produced at spec diameter.

3/30

What I did :

Set up control loop,

Re calibrate sensor.

ToDo list :

Debug control loop to accurately predict the filament diameter

Concerns

Inconsistent readings due to electromagnet field difference.

4/6/2025;

Ran for a consistent diameter. Motor Overheated

ToDO: install a new heatsink on motor

Rerun for a full spool of filament.

4/13/2025

STARTED report draft

Started drying filament in the lab also (TPU hopefully saving a couple rolls)

4/20/2025

Continue report editations

thank you to the fish team for the good edits.

Fall 2025

This year, I’ve started by developing a project roadmap, reaching out to the Framework’s company, preparing documentation, and working towards the future development of this project. I have also worked on developing a project.

We have also made post on a community page for the framework’s system.