WEEK 4 – Project Update 3

- PAST WEEK:

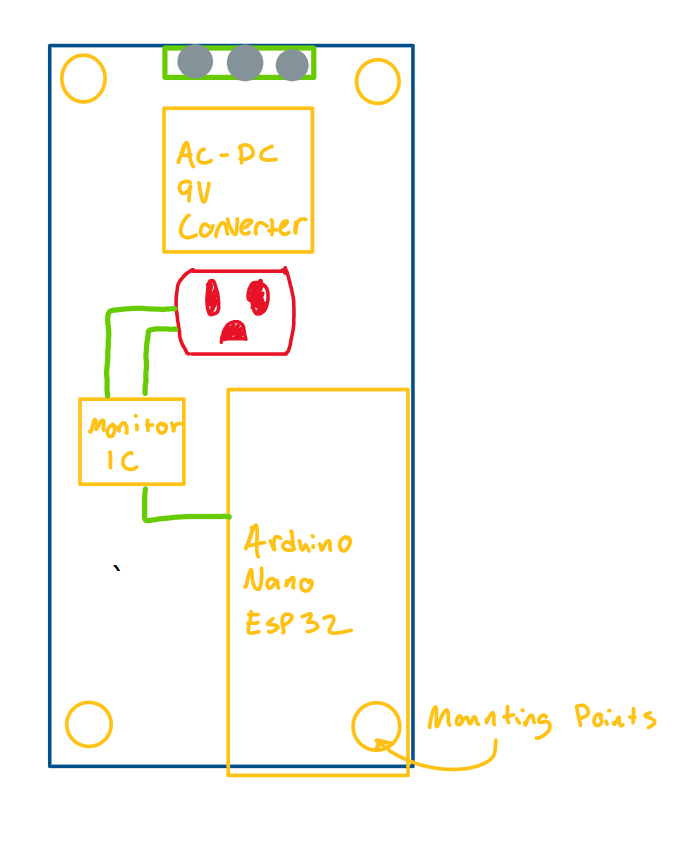

- Soldered the our system’s primary IC, the power sensing module, to a breakout board to allow for further testing and implementation.

- Re-imagined power routing scheme to ensure correct functionality.

- TODO:

- Integrate the necessary modules to run DC consumption tests on a breadboard.

- This will allow us to confirm communication protocol between the Arduino and the IC.

- Integrate the necessary modules to run DC consumption tests on a breadboard.

- CONCERNS:

- I am worried that we are making slow progress. In the coming week I will devote more hours to this project than I have in the past week.

WEEK 4 – Project Update 2

- PAST WEEK:

- We collectively determined that the current PCB prototype has some glaring design flaws and it is not worth dedicating effort to diagnosing/fixing physical issues.

- The issues with I2C communication were likely electrical routing issues rather than software.

- Ordered new components to enable breadboard testing of full system components.

- TODO:

- Rewrite code to communicate via SPI for new board.

- Test smaller programming subsystems that do not depend on new PCB (i.e. webserver hosting)

- CONCERNS:

- Designing and ordering a new PCB will take a lot of time.

- Software is CRUCIAL for a working final product and it will be at least a couple of weeks before comprehensive testing can be conducted.

WEEK 3 – Project Update 1

- TODO:

- Diagnose the reason for 0 information transfer on the I2C bus between MCU and IC.

- Review electrical diagrams for PCB.

- Review I2C documentation for Arduino’s Wire library.

- Correct pin assignments in the Arduino software.

- Write “Hello world” program that will provide voltage and amperage levels to a user via serial terminal.

- Establish communication on the I2C bus.

- Parse IC’s register information into human-readable floating point values.

- Diagnose the reason for 0 information transfer on the I2C bus between MCU and IC.

- CONCERNS:

- My initial testing of the system software yielded 0 transfer of information between the MCU and the IC. This could mean one of three things:

- Power monitor IC is fried and must be replaced.

- The IC has been soldered to the board in the wrong orientation.

- The software has been written incorrectly.

- My initial testing of the system software yielded 0 transfer of information between the MCU and the IC. This could mean one of three things: